E le mofani ea ka sehloohong oa lisebelisoa tsa aluminium tsa premium lelits'ebeletso tse nepahetseng tsa mochini oa CNC, Shanghai Miandi Metal Products Co., Ltd. e ikakhetse ka setotsoana ho fana ka lialloi tsa aluminium tse sebetsang hantle haholo tse ntlafalitsoeng bakeng sa ho sila, ho reteleha le ho etsoa ha CNC. Hore na o hloka lisebelisoa tse bobebe tse nang le li-geometri tse rarahaneng kapa likarolo tse matla haholo bakeng sa liindasteri tse boima, boiphihlelo ba rona ba khetho ea alloy le machining bo netefatsa ho nepahala le ho ts'epahala ho ke keng ha bapisoa.

1. Lisebelisoa tsa bohlokoa tsa Aluminium bakeng sa CNC Machining

CNC machining e hloka li-alloys tse leka-lekaneng machinability, botsitso ba sebopeho, pheletso ea bokaholimo le thepa ea mochini. Ka tlase ke letoto la aluminium le sebelisoang ka ho fetesisa le melemo ea bona e ikhethang:

a. 6000 Series Aluminium (6061, 6063)

Sebopeho sa Core: Silicon (Si) le magnesium (Mg) e le likarolo tse ka sehloohong tsa motsoako (mohlala, 6061: 0.6% Si, 1.0% Mg).

Machinability: Ho etsoa ka mokhoa o babatsehang oa li-chips le matla a tlaase a ho itšeha, a loketseng bakeng sa ts'ebetso ea CNC e lebelo.

Thepa ea Mechini: Matla a itekanetseng (UTS: 260–310 MPa ka T6 temper), ho hanyetsa kutu e ntle, le ho chesehela.Mocheso o phekolehang (T4/T6 tempering) bakeng sa boima bo matlafalitsoeng le botšepehi ba sebopeho.

Lisebelisoa tse tloaelehileng: Li-brackets tsa Aerospace, likarolo tsa likoloi, likarolo tsa liroboto, le li-extrusions tsa aluminium.

Ke Hobane'ng ha U Re Khetha: Re fana ka lipoleiti / lithupa tsa aluminium tsa 6061-T6 / T651 tse nang le mamello e tiileng ea mahlakore (± 0.01 mm), e itokiselitseng ho sila ka mokhoa o phahameng oa CNC.

b. 7000 Series Aluminium (7075)

Sebopeho sa Core: Zinc (Zn) e le motlatsi oa mantlha, ka Mg le Cu (mohlala, 7075: 5.6% Zn, 2.5% Mg).

Machinability: Boima bo phahameng ho feta letoto la 6000 le hloka lisebelisoa tsa carbide kapa PCD, empa li fana ka mokhoa o phahameng oa ho itšeha ka mokhoa o nepahetseng bakeng sa libopeho tse rarahaneng.Ho hanyetsa ka mokhoa o babatsehang ho deformation nakong ea machining e boima.

Mechanical Properties: Ultra-high matla (UTS: ho fihlela ho 572 MPa ka T651 temper), e etsa hore e be matla ho feta litšepe tse ngata ha e ntse e lula e le bobebe.Ho hanyetsa mokhathala o phahameng, ho bohlokoa bakeng sa lisebelisoa tsa sefofane le khatello e phahameng ea indasteri.

Lisebelisoa tse tloaelehileng: Likarolo tsa sebopeho sa sefofane (mohlala, likarolo tsa mapheo), chassis ea motorsport, le hlobo e nepahetseng.

Molemo oa rona: Lithupa / lipoleiti tsa aluminium tsa Premium 7075-T651 tse nang le li-annealing tse fokotsang khatello ea maikutlo, tse fokotsang leqephe la ntoa le bakoang ke machining.

c. 2000 Series Aluminium (2024)

Sebopeho sa Core: Koporo (Cu) e thehiloeng ka Mg / Mn (mohlala, 2024: 4.4% Cu, 1.5% Mg).

Machinability:Machinability e ntle (haholo-holo libakeng tse annealed) bakeng sa ho fetola CNC le ho sila, le hoja bohale bo thata (T8) bo hloka lisebelisoa tse matla.

Mechanical Properties:Matla a phahameng (UTS: 470–485 MPa in T351 temper) le khatelo-pele e ntle ea mokhathala.Mocheso o ka phekoleha bakeng sa boima bo ntlafalitsoeng lits'ebetsong tsa ho jara mojaro.

Tšebeliso e tloaelehileng: Li-spars tsa mapheo a sefofane, likarolo tsa lisebelisoa tsa ho lulisa, le lisebelisoa tsa mochini tse sebetsang hantle haholo.

d. 5000 Series Aluminium (5052, 5083)

Sebopeho sa Core: Magnesium (Mg) -e ruileng (mohlala, 5052: 2.5% Mg).

Machinability: Soft le ductile, e loketseng bakeng saCNC ho theha le ho kobeha ntle lecracking. Qetello e ntle haholo ya bokahodimo bakeng sa mekgabiso kapa dikarolo tse baballang kutu.

Mechanical Properties:Matla a itekanetseng a nang le matla a ho thibela kutu (a loketseng tikoloho ea leoatle kapa ea kantle). Ha a phekolehe mocheso, empa ho thatafatsa mosebetsi ho matlafatsa nako e telele.

Tšebeliso e tloaelehileng: Likarolo tsa likepe, lisebelisoa tsa lik'hemik'hale, le likarolo tse khabisitsoeng ka mochini oa CNC.

Tlhahiso ea rona: lipoleiti tsa aluminium tsa 2024-T351 tse netefalitsoeng bakeng sa maemo a sefofane (mohlala, AMS 4042).

2. CNC Machining Melemo ea Aluminium Alloys

a. Material Properties Optimized for Precision

Boima bo Tlase: 2.7 g/cm³ (1/3 boima ba tšepe), e fokotsang matla a ho sebetsa ka potlako le lihlahisoa tse bobebe.

Thermal Conductivity: Ho senya mocheso o phahameng ho fokotsa ho roala ha lisebelisoa le ho senyeha ha mocheso nakong ea ho itšeha ka lebelo le phahameng.

Isotropic Behaviour: Thepa e ts'oanang ea mochini ka mahlakoreng 'ohle, e netefatsa liphetho tse tsitsitseng tsa mochini.

b. Bokhoni ba ho sebetsa ka mokhoa o nepahetseng le ho sebetsa ka litšenyehelo

Mabelo a Phahameng a ho Seha: Aluminium e lumella litefiso tsa fepa ho fihlela ho 5000 mm / min (ho itšetlehile ka alloy), ho fokotsa linako tsa potoloho.

Tšebelisano ea Sesebelisoa: E lumellana le lisebelisoa tsa carbide, HSS, le PCD, e fanang ka maemo a bonolo bakeng sa ho qhekella le ho qeta ts'ebetso.

Taolo ea Chip: Li-alloy tsa Ductile tse kang 6061 li hlahisa li-chips tse tsoelang pele, ha limaraka tsa mahala tsa machining (mohlala, 6061 tse nang le Pb / Bi) li hlahisa li-chips tse robehang bakeng sa mochine o ikemetseng.

c. Ka mor'a Ts'ebetso ea Fetola

Ho Felisa Bokahohle: Anodizing, ho roala phofo, electroplating, kapa ho phatloha ha lifaha ho matlafatsa botle le ho hanyetsa ho bola.

Kalafo ea Mocheso: Ho futhumatsa ka tloaelo (mohlala, T6) ho fihlela boima ba sepheo le ho imolla khatello ea maikutlo ka mor'a ho sebetsa.

3. Shanghai Miandi's CNC Machining Solutions bakeng sa Aluminium

Ntlafatsa bokhoni ba rona ba ho qetela ho isa qetellong ho fetola lialloi tsa aluminium hore e be likarolo tse nepahetseng:

a. Phepelo ea Lintho

Letoto le felletseng la alloy ea aluminium: 6061, 7075, 2024, 5052 ka lipoleiti, lithupa, li-tubes, le li-extrusions tse tloaelehileng, tse nkiloeng ho tloha lifemeng tse tiisitsoeng.

Likhetho tsa ho halefa: Li-Annealed (O), tse nang le tharollo (T4), ea tsofetseng (T6), le tse fokotsang khatello ea maikutlo (T651) ho fihlela litlhoko tsa machining le ts'ebetso.

b. Litšebeletso tsa CNC tse nepahetseng

Bokhoni ba ho Macha:

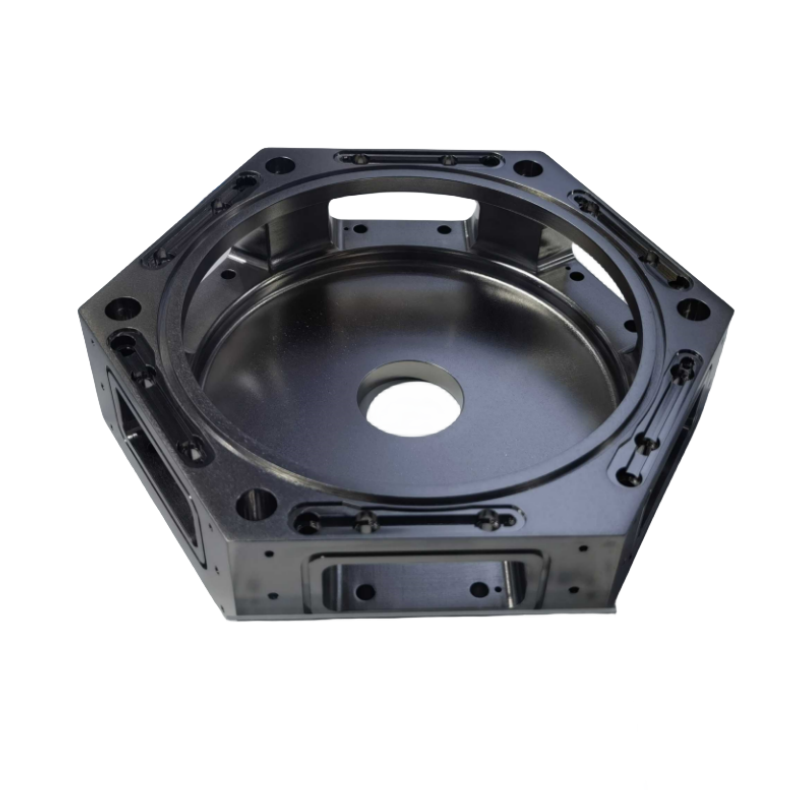

3/4/5-axis CNC milling bakeng sa lijeometri tse rarahaneng (mohlala, masakana a sepakapaka, lisebelisoa tsa bongaka).

CNC ho fetola li-shafts, hubs, le likarolo tsa cylindrical (mamello: ± 0.005 mm).

Machine oa Switzerland bakeng sa likarolo tse nepahetseng tse nyane (bophara: 0.5-20 mm).

Ts'ebetso e thusang: Ho cheka, ho tlanya, ho roka, ho roka, le EDM bakeng sa likarolo tse rarahaneng.

c. Netefaletso ea boleng

ISO 9001: 2015 E netefalitsoeng: Tlhahlobo e matla ea k'hemistri ea thepa, thepa ea mochini, le ho nepahala ha dimensional (CMM/optical measurement).

Tšehetso ea DFM: Therisano ea mahala ea moralo bakeng sa mochini ho ntlafatsa karolo ea geometry bakeng sa litšenyehelo le katleho.

d. Customization & Scalability

Mehlala e nyane ea batch ho tlhahiso e phahameng haholo, e nang le phetoho e potlakileng (matsatsi a 7-10 bakeng sa prototypes).

Tumellano ea indasteri: Lisebelisoa tse netefalitsoeng ho latela maemo a ASTM, AMS, GB, kapa ISO, tse nang le litokomane tse ka lateloang bakeng sa bareki ba sefofane le likoloi.

4. Ke Hobane'ng ha U Khetha Aluminium bakeng sa CNC Machining?

Boima ba Boima: E loketse lits'ebetso moo moralo o bobebe o leng bohlokoa (mohlala, sefofane, li-drones).

Litšenyehelo: Litšenyehelo tse tlase tsa thepa le mochini ho feta titanium kapa tšepe, e nang le bokhoni bo botle ba ho sebelisoa hape.

Tokoloho ea Moralo: Libopeho tse rarahaneng, mabota a manyane, le mamello e tiileng e ka fihlellehang ka lisebelisoa tsa sejoale-joale tsa CNC.

Ikopanye le Shanghai Miandi Kajeno bakeng sa ho lokisoaLitharollo tsa machining tsa CNC li sebelisa li-alloys tsa aluminium tsa premium. Hore na o hloka prototype e le 'ngoe kapa likarolo tse hlahisoang ka bongata, boiphihlelo ba rona ba khetho ea li-alloy, ho nepahala ha mochini, le taolo ea boleng bo netefatsa hore projeke ea hau e ea atleha.

Shanghai Miandi Metal Products Co., Ltd. - Precision in Every Cut.

Nako ea poso: Jun-12-2025