A matsayin babban mai samar da kayan aikin aluminium mai ƙima damadaidaicin sabis na injin CNC, Shanghai Miandi Metal Products Co., Ltd. ya ƙware a cikin isar da manyan kayan aikin aluminum waɗanda aka inganta don milling CNC, juyawa, da ƙirƙira. Ko kuna buƙatar abubuwan sassauƙa masu nauyi tare da rikitattun geometries ko sassa masu ƙarfi don masana'antu masu buƙata, ƙwarewarmu a zaɓin gami da machining yana tabbatar da daidaito da amincin da ba su dace ba.

1. Key Aluminum Alloys don CNC Machining

CNC machining yana buƙatar gami waɗanda ke daidaita machinability, kwanciyar hankali mai girma, ƙarewar ƙasa, da kaddarorin inji. A ƙasa akwai jerin abubuwan da aka fi amfani da su na aluminum da fa'idodin su na musamman:

a. 6000 Series Aluminum (6061, 6063)

Babban Abun Haɗawa: Silicon (Si) da magnesium (Mg) azaman abubuwan haɗakarwa na farko (misali, 6061: 0.6% Si, 1.0% Mg).

Machinability: Excellent guntu samuwar da ƙananan yankan sojojin, manufa domin high-gudun CNC ayyuka.Smooth surface gama (Ra ≤ 1.6μm) achievable ba tare da m post-aiki.

Kayan aikin injiniya: Ƙarfin matsakaici (UTS: 260-310 MPa a cikin T6 fushi), tsayayyar lalata mai kyau, da weldability.Heat-treatable (T4 / T6 tempering) don haɓaka taurin da tsarin tsarin.

Aikace-aikace na yau da kullun: Maɓallan sararin samaniya, kayan aikin mota, sassa na robotics, da extrusions na aluminum.

Me yasa Zabi Mu: Muna ba da faranti na aluminium / sanduna 6061-T6 / T651 tare da juzu'i mai ƙarfi (± 0.01 mm), shirye don milling CNC mai tsayi.

b. 7000 Series Aluminum (7075)

Mahimmin Ƙarfafawa: Zinc (Zn) a matsayin mai ƙarfafawa na farko, tare da Mg da Cu (misali, 7075: 5.6% Zn, 2.5% Mg).

Machinability: Higher hardness fiye da 6000 jerin bukatar carbide ko PCD kayan aikin, amma yayi m yankan daidaici ga hadaddun siffofi.Excellent juriya ga nakasawa a lokacin nauyi machining.

Kayan aikin injiniya: Ƙarfin Ƙarfin Ƙarfi (UTS: har zuwa 572 MPa a cikin T651 fushi), yana sa ya fi karfi fiye da yawancin karfe yayin da ya rage nauyi.High gajiya juriya, mai mahimmanci ga sararin samaniya da aikace-aikacen masana'antu mai tsanani.

Aikace-aikace na yau da kullun: Sassan tsarin jirgin sama (misali, abubuwan haɗin reshe), chassis na motsa jiki, da madaidaicin ƙira.

Amfanin mu: Premium 7075-T651 aluminum sanduna / faranti tare da rage damuwa annealing, rage machining-induced shafi na.

c. 2000 Series Aluminum (2024)

Babban Haɗin Kai: Copper (Cu) tare da Mg/Mn (misali, 2024: 4.4% Cu, 1.5% Mg).

Machinability: Kyakkyawan inji (musamman a cikin jahohin da ba a kwance ba) don juyawa da milling na CNC, kodayake zafin fushi (T8) yana buƙatar kayan aiki mai ƙarfi.Mai ikon samun juriya ga abubuwan haɗin sararin samaniya.

Kayan aikin injiniya: Ƙarfi mai ƙarfi (UTS: 470-485 MPa a cikin T351 fushi) da kuma kyakkyawan juriya na gajiya. Zazzabi mai zafi don ingantaccen taurin a cikin aikace-aikacen ɗaukar nauyi.

Aikace-aikace na yau da kullun: spars reshe na jirgin sama, sassan kayan saukarwa, da manyan abubuwan injina.

d. 5000 Series Aluminum (5052, 5083)

Babban Abun Haɗin: Magnesium (Mg) - mai arziki (misali, 5052: 2.5% Mg).

Machinability: Soft da ductile, manufa donCNC kafa da lankwasawa ba tare dacracking.Kyakkyawan shimfidar wuri don kayan ado ko lalata-m sassa.

Kayayyakin Injini:Matsakaicin ƙarfi tare da juriya na musamman na lalata (madaidaicin yanayin ruwa ko waje).Waɗanda ba za a iya magance zafi ba, amma taurin aiki yana haɓaka dorewa.

Aikace-aikace na yau da kullun: Rukunin jirgin ruwa, kayan aikin sinadarai, da kayan ado na injinan CNC.

Bayar da Mu: 2024-T351 aluminum faranti ƙwararrun ma'auni na sararin samaniya (misali, AMS 4042).

2. CNC Machining Abvantbuwan amfãni na Aluminum Alloys

a. Abubuwan Kayayyakin Kayan Aiki Don Daidaitawa

Ƙarƙashin Ƙarfafa: 2.7 g/cm³ (1/3 nauyin karfe), rage rashin aiki don yin aiki da sauri da samfurori masu sauƙi.

Ƙarfafawar thermal: Babban zafi mai zafi yana rage girman kayan aiki da nakasar zafi yayin yankan sauri.

Halayyar Isotropic: Kaddarorin injina na Uniform a duk kwatance, yana tabbatar da daidaiton sakamakon injin.

b. Ingantacciyar Machining & Tasirin Kuɗi

Babban Yankan Gudu: Aluminum yana ba da damar ƙimar ciyarwa har zuwa 5000 mm / min (dangane da gami), rage lokutan sake zagayowar.

Daidaituwar Kayan aiki: Mai jituwa tare da carbide, HSS, da kayan aikin PCD, suna ba da sassauci don roughing da kammala ayyukan.

Sarrafa Chip: Ductile alloys kamar 6061 suna samar da kwakwalwan kwamfuta masu ci gaba, yayin da matakan injina kyauta (misali, 6061 tare da ƙara Pb/Bi) suna haifar da kwakwalwan kwamfuta masu karɓuwa don injina mai sarrafa kansa.

c. Sassaucin Sassauta Bayan-Aiki

Ƙarshen Sama: Anodizing, murfin foda, electroplating, ko fashewar katako don haɓaka ƙaya da juriya na lalata.

Jiyya na Zafi: Halin yanayi na al'ada (misali, T6) don cimma taurin manufa da sauƙi na damuwa bayan injin.

3. Shanghai Miandi's CNC Machining Solutions for Aluminum

Yi amfani da ƙarfin mu na ƙarshe zuwa ƙarshe don canza allunan aluminium zuwa madaidaicin sassa:

a. Kayayyakin Kaya

Cikakken jerin gwanon aluminium: 6061, 7075, 2024, 5052 a cikin faranti, sanduna, tubes, da extrusions na al'ada, waɗanda aka samo daga ingantattun masana'anta.

Zaɓuɓɓukan zafin rai: Annealed (O), maganin maganin (T4), tsofaffi (T6), da kuma rage damuwa (T651) don saduwa da machining da bukatun aiki.

b. Madaidaicin Sabis na CNC

Ƙarfin injina:

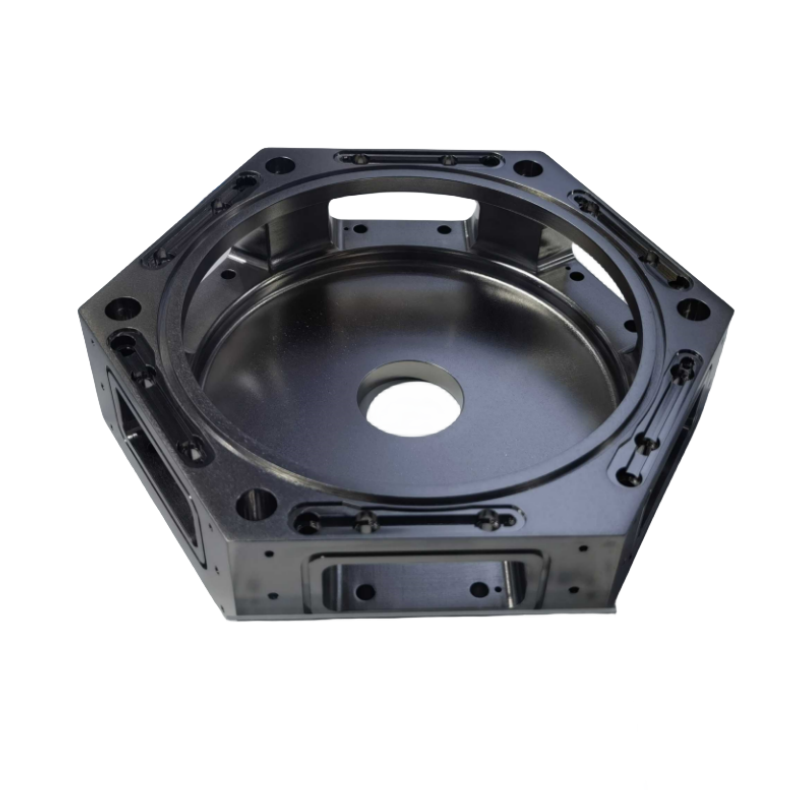

3/4/5-axis CNC milling don hadadden geometries (misali, aerospace brackets, likita na'urorin).

CNC yana jujjuyawa don shafts, cibiyoyi, da sassan cylindrical (haƙuri: ± 0.005 mm).

Machining na Swiss don ƙayyadaddun ƙayyadaddun ƙananan ƙananan (diamita: 0.5-20 mm).

Tsarin taimako: hakowa, taɓo, zaren zare, broaching, da EDM don ƙaƙƙarfan fasali.

c. Tabbacin inganci

TS EN ISO 9001: 2015 Takaddun shaida: Tsare-tsare na binciken sunadarai na kayan, kaddarorin injiniyoyi, da daidaiton girman (CMM / ma'aunin gani).

Tallafin DFM: Shawarar ƙira-don-inji kyauta don haɓaka juzu'i don farashi da inganci.

d. Keɓancewa & Ƙarfafawa

Samfurin ƙaramin tsari zuwa samarwa mai girma, tare da saurin juyawa (kwanaki 7-10 don samfura).

Yarda da masana'antu: Abubuwan da aka tabbatar da su zuwa matsayin ASTM, AMS, GB, ko ISO, tare da takaddun ganowa don sararin samaniya da abokan cinikin mota.

4. Me yasa Zabi Aluminum don CNC Machining?

Ma'aunin Ƙarfin Nauyi: Mafi dacewa don aikace-aikace inda ƙirar nauyi ke da mahimmanci (misali, sararin samaniya, jirage marasa matuki).

Ƙimar-Tasiri: Ƙananan kayan abu da farashin injina fiye da titanium ko karfe, tare da ingantaccen sake yin amfani da su.

'Yancin Zane: Sifurori masu rikitarwa, bangon bakin ciki, da kuma juriya masu ƙarfi waɗanda za'a iya cimma su tare da kayan aikin CNC na zamani.

Tuntuɓi Shanghai Miandi A yau don keɓancewaCNC machining mafita ta amfani da premium aluminum gami. Ko kuna buƙatar samfuri ɗaya ko abubuwan da aka samar da jama'a, ƙwarewarmu a zaɓin gami, daidaiton mashin ɗin, da sarrafa inganci yana tabbatar da nasarar aikinku.

Shanghai Miandi Metal Products Co., Ltd. - Daidaitawa a kowane Yanke.

Lokacin aikawa: Juni-12-2025