Ama-alloys e-aluminiumidlala indima ebalulekile embonini ye-semiconductor, ngokusetshenziswa kwayo okubanzi okunomthelela omkhulu. Nasi isifinyezo sendlela ama-alloys e-aluminium anomthelela ngayo embonini ye-semiconductor kanye nokusebenza kwawo okuqondile:

I. Izicelo zeAluminiyamu Alloysku Semiconductor Manufacturing

1. Izisetshenziswa Zesakhiwo Sezisetshenziswa:

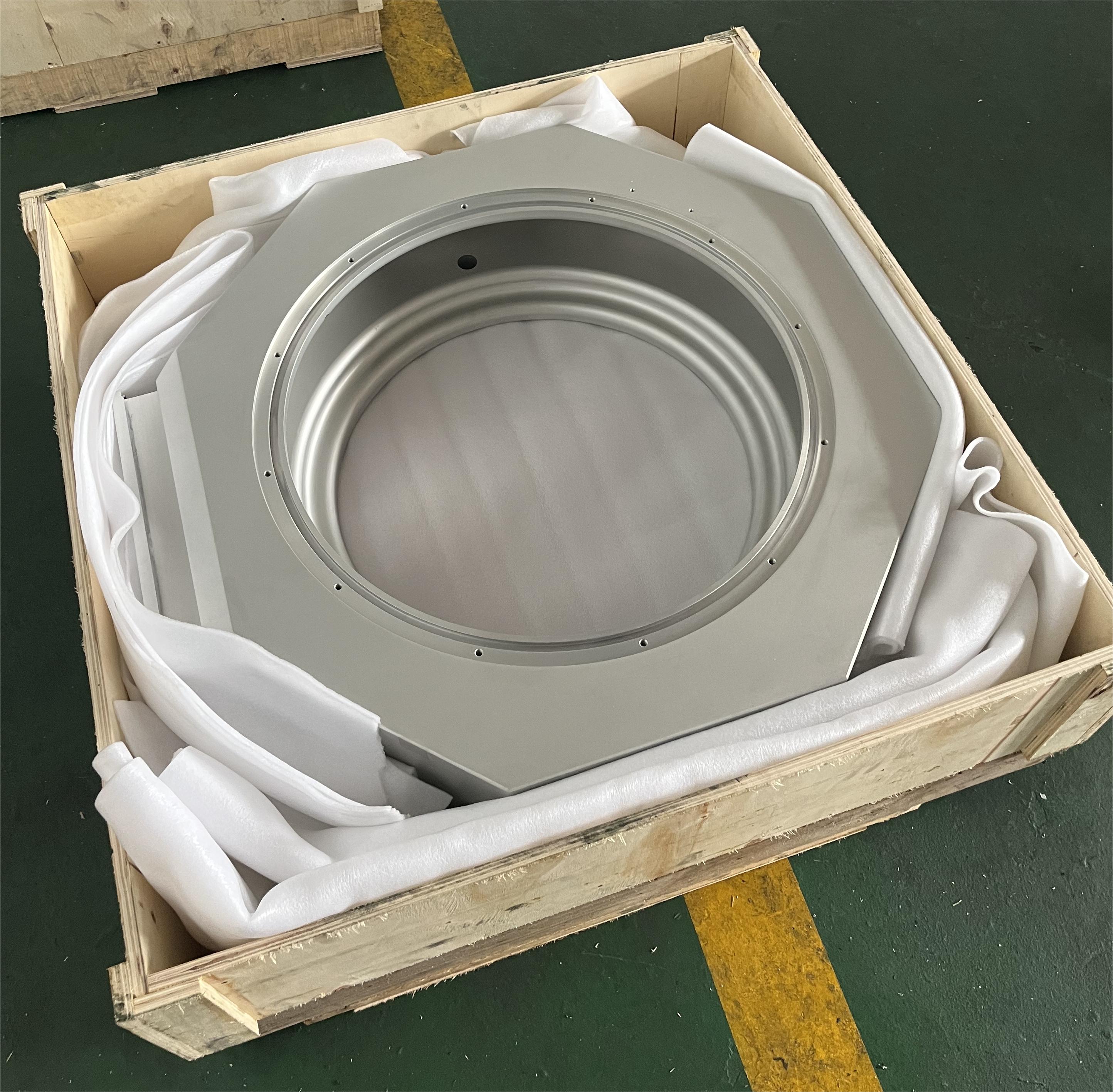

- Ama-Vacuum Chambers: Ama-alloys e-Aluminium asetshenziselwa ukwakha amakamelo omshini we-semiconductor ngenxa yezakhiwo zawo ezinhle kakhulu zemishini kanye nokushisa okushisayo. Lawa makamelo adinga ukumelana namazinga okushisa aphezulu kanye nezingcindezi ngenkathi egcina indawo ene-vacuum ephezulu.

- Izisekelo namafreyimu**: Ama-alloys e-aluminium, njengoba engasindi kodwa eqinile, asetshenziswa kabanzi ukwenza izisekelo namafreyimu emishini, enciphisa isisindo sisonke futhi andise ukuguquguquka kokusebenza.

2. Izingxenye Zokukhipha Ukushisa:

- Ama-Heat Sinks: Ama-alloys e-aluminium, awaziwa ngokusebenza kahle kakhulu kokushisa, avame ukusetshenziselwa ukwenza amasinki okushisa emishini ye-semiconductor, okusiza ukuqeda ukushisa ngokushesha nokuqinisekisa ukusebenza okuzinzile kwemishini.

- Amapuleti Okupholisa: Amapuleti okupholisa ama-aluminium alloy asetshenziswa ezinhlelweni zokupholisa zemishini ye-semiconductor ukuze ehlise amazinga okushisa ngempumelelo, athuthukise ukuthembeka nempilo yokuphila kwemikhiqizo.

3. Amadivayisi okuphatha ama-wafer:

- Izingalo zeRobhothi: Izingalo zerobhothi ezisetshenziselwa ukudlulisa ama-wafers ngesikhathi sokukhiqizwa kwe-semiconductor ngokuvamile zenziwe ngama-alloys e-aluminium. Izakhiwo ezingasindi futhi eziphakeme kakhulu zama-alloys e-aluminium ziwenza abe ukukhetha okuhle, okuqinisekisa ukudluliswa kwe-wafer okunembe nokusheshayo.

II. Izicelo ze-Aluminium Alloys ku-Semiconductor Materials

1. Izixhumi zensimbi:

- I-Aluminium Interconnects: I-Aluminium nama-alloys ayo asetshenziswa kabanzi njengezinto zokuxhuma ngaphakathi kwama-chip. Naphezu kokuxhumana kwethusi kancane kancane kungena esikhundleni se-aluminium eminyakeni yamuva, i-aluminium isabalulekile kwezinye izinhlelo zokusebenza ngenxa ye-conductivity yayo enhle kanye nokusebenza kahle kwezindleko.

2. Izinto Zokupakisha:

- I-Aluminium Alloy Packaging: Ama-alloys e-aluminium asetshenziswa ekufakweni kwedivayisi ye-semiconductor ukuze anikeze uxhumano olusebenzayo lukagesi kanye nokuvikelwa komshini ngenkathi enikeza ukusebenza okuhle kokushisa ukuze kuqinisekiswe ukwethembeka kwamadivayisi ngesikhathi sokusebenza okuphezulu.

III. Izinzuzo ze-Aluminium Alloys embonini ye-Semiconductor

1. Amandla Angasindi Naphezulu:

- Imvelo engasindi yama-alloys e-aluminium inciphisa isisindo sonke semishini nezingxenye, ithuthukisa ukukhiqiza nokusebenza kahle.

2. I-Thermal Conductivity Enhle Kakhulu:

- Ukusebenza kwabo okuhle kakhulu kwe-thermal kwenza ama-alloys e-aluminium enze kahle ekusetshenzisweni kokukhipha ukushisa, ukuqinisekisa ukuthi imishini ye-semiconductor igcina izinga lokushisa elifanele ngesikhathi sokusebenza okuphezulu.

3. Ukusebenza Okuhle:

- Ama-alloys e-aluminium kulula ukuwenza ngomshini nokwenza, ahlangabezana nezidingo eziqondile zokucubungula zemishini ye-semiconductor kanye nezingxenye.

4. Ukumelana Nokugqwala:

- Ukumelana nokugqwala kwama-alloys e-aluminium kuwanika isikhathi eside sokuphila ezindaweni ezinokhahlo zokukhiqiza ama-semiconductor, kunciphisa imvamisa yokugcinwa kwemishini nokushintshwa.

IV. Amathemba Ekusasa

1. Ukuthuthukiswa Kwezinto Ezibalulekile:

- Ngokuthuthuka kobuchwepheshe be-semiconductor, izidingo zokusebenza zezinto zokwakha zikhula ngokuqhubekayo. Ukwakheka nokucutshungulwa kwama-alloys e-aluminium kuzothuthukiswa njalo ukuze kuhlangatshezwane ne-conductivity ephezulu, ukuqhutshwa kwe-thermal, kanye nezidingo zamandla emishini.

2. Ukuthuthukiswa Kwezicelo Ezintsha:

- Ubuchwepheshe obusafufusa be-semiconductor (njenge-quantum computing kanye ne-flexible electronics) bungase bulethe izimfuno ezintsha zezinto ze-aluminium alloy. Ucwaningo nokuthuthukiswa kwezinto ezintsha ze-aluminium alloy kanye nezicelo kuzoba isiqondiso esibalulekile esikhathini esizayo.

3. Ukuvikelwa Kwemvelo Nokusimama:

- Izici zokuphinda zisetshenziswe nezici zokuphinda zisetshenziswe zama-alloys e-aluminium ziwanikeza izinzuzo ekuvikelweni kwemvelo kanye nokusimama. Ngokuzayo, imboni ye-semiconductor izogcizelela kakhulu ukugaywa kabusha kwezinto kanye nomthelela wemvelo, ikhuthaze ukusetshenziswa nokuthuthukiswa kwama-alloys e-aluminium.

Ngokufigqiwe,ama-alloys e-aluminiumibe nomthelela omkhulu embonini ye-semiconductor, idlala indima ebalulekile ekwenziweni kwemishini, ukusetshenziswa kwezinto ezibonakalayo, kanye nokuthuthukiswa kobuchwepheshe. Njengoba ubuchwepheshe buqhubeka futhi bufuna ushintsho, ukusetshenziswa kwama-alloys e-aluminium embonini ye-semiconductor kuzoqhubeka nokukhula nokujula.

Isikhathi sokuthumela: Jul-05-2024