Njengomhlinzeki oholayo wezinto zokwakha ze-aluminium ze-premium kanyeukunemba kwezinsizakalo zemishini ye-CNC, I-Shanghai Miandi Metal Products Co., Ltd. igxile ekuletheni ama-alloys e-aluminium asebenza kahle kakhulu alungiselelwe ukugaya, ukuphenduka, nokwenza izinto nge-CNC. Noma ngabe udinga izingxenye ezingasindi ezinamajiyometri ayinkimbinkimbi noma izingxenye eziqine kakhulu zezimboni ezifuna ngamandla, ubuchwepheshe bethu ekukhetheni ingxubevange nokwenza imishini buqinisekisa ukunemba nokuthembeka okungenakuqhathaniswa.

1. Ama-Aluminium Alloys Abalulekile we-CNC Machining

I-CNC machining idinga ama-alloys abhalansisa ukusebenza kahle, ukuqina kwe-dimensional, ukuqedwa kwendawo, kanye nezakhiwo zemishini. Ngezansi kukhona uchungechunge lwe-aluminium olusetshenziswa kakhulu kanye nezinzuzo zalo eziyingqayizivele:

a. 6000 Series Aluminium (6061, 6063)

Ukubunjwa Okuyinhloko: I-Silicon (Si) ne-magnesium (Mg) njengezakhi eziyinhloko ze-alloying (isb, 6061: 0.6% Si, 1.0% Mg).

I-Machinability: Ukwakheka kwe-chip okuhle kakhulu namandla okusika aphansi, alungele ukusebenza kwe-CNC enesivinini esiphezulu.I-Smooth surface finish (Ra ≤ 1.6μm) efinyelelekayo ngaphandle kokucutshungulwa okubanzi kwangemuva.

Izakhiwo Zemishini: Amandla amaphakathi (i-UTS: 260–310 MPa ku-T6 temper), ukumelana nokugqwala okuhle, kanye nokushisela.Ukushisa okulawulekayo (T4/T6 tempering) kokuqina okuthuthukisiwe kanye nobuqotho besakhiwo.

Izinhlelo zokusebenza ezijwayelekile: Abakaki be-Aerospace, izingxenye zezimoto, izingxenye zamarobhothi, nama-aluminum extrusions.

Kungani Sikhethe: Sinikeza amapuleti/izinduku ze-aluminium ezingu-6061-T6/T651 ezinokubekezelelana okuqinile (±0.01 mm), alungele ukugaya okunemba okuphezulu kwe-CNC.

b. 7000 Series Aluminium (7075)

Ukubunjwa Okuyinhloko: I-Zinc (Zn) njengesiqinisi esiyinhloko, nge-Mg ne-Cu (isb, 7075: 5.6% Zn, 2.5% Mg).

I-Machinability: Ukuqina okuphezulu kunochungechunge lwe-6000 kudinga amathuluzi e-carbide noma e-PCD, kodwa kunikeza ukunemba okusika okuphezulu kokuma okuyinkimbinkimbi.Ukumelana okuhle kakhulu nokuguqulwa ngesikhathi somshini onzima.

Izakhiwo Zemishini: Amandla aphezulu kakhulu (i-UTS: kufika ku-572 MPa ku-T651 temper), okuyenza ibe namandla kunezinsimbi eziningi kuyilapho ihlala ingasindi.Ukumelana nokukhathala okuphezulu, okubalulekile kwi-aerospace kanye nezinhlelo zokusebenza zezimboni ezinokucindezeleka okuphezulu.

Izinhlelo zokusebenza ezijwayelekile: Izingxenye zesakhiwo sendiza (isb, izingxenye zamaphiko), i-motorsport chassis, kanye nokubunjwa okunembayo.

Inzuzo Yethu: Izinti/amapuleti e-aluminium e-Premium 7075-T651 ane-anneal eqeda ukucindezeleka, anciphisa ikhasi lempi elenziwa ngomshini.

c. 2000 Series Aluminium (2024)

Ukubunjwa Okuyinhloko: I-Copper (Cu)-based with Mg/Mn (isb, 2024: 4.4% Cu, 1.5% Mg).

Ukusebenziseka kalula:Ukusebenziseka kahle (ikakhulukazi ezifundeni ezishubile) kokuphenduka nokugaya kwe-CNC, nakuba ulaka oluqinile (T8) ludinga amathuluzi aqinile.Okukwazi ukufeza ukubekezelelana okuqinile kwezingxenye zebanga le-aerospace.

Izakhiwo Zemishini:Amandla aphezulu (i-UTS: 470–485 MPa ku-T351 intukuthelo) kanye nokumelana nokukhathala okuhle kakhulu.Kuyelapheka ngenxa yokuqina okuthuthukisiwe ezinhlelweni zokuthwala umthwalo.

Uhlelo lokusebenza olujwayelekile:Izimpaphe zamaphiko endiza, izingxenye zegiya lokuhlala, nezingxenye zemishini ezisebenza kahle kakhulu.

d. 5000 Series Aluminium (5052, 5083)

Ukwakhiwa Okuyinhloko: I-Magnesium (Mg)-ecebile (isb, 5052: 2.5% Mg).

I-Machinability: Ithambile futhi i-ductile, ilungeleCNC ukwakha nokugoba ngaphandleukuqhekeka.Isiphetho esihle kakhulu sezingxenye zokuhlobisa noma ezizwela ukugqwala.

Izakhiwo Zemishini:Amandla amaphakathi anokumelana nokugqwala okukhethekile (ilungele indawo yasolwandle noma yangaphandle).Akulapheki ukushisa, kodwa ukuqinisa umsebenzi kuthuthukisa ukuqina.

Uhlelo lokusebenza olujwayelekile: Izikebhe zesikebhe, okokusebenza kwamakhemikhali, nezinto zokuhlobisa ezenziwe ngomshini we-CNC.

Ukunikezwa kwethu: amapuleti e-aluminium angu-2024-T351 agunyazwe amazinga we-aerospace (isb, i-AMS 4042).

2. CNC Machining Izinzuzo Aluminium Alloys

a. Izinto Ezibalulekile Zenzelwe Ukunemba

Ukuminyana Okuphansi: 2.7 g/cm³ (1/3 isisindo sensimbi), kunciphisa inertia yomshini osheshayo kanye nemikhiqizo yokugcina elula.

I-Thermal Conductivity: Ukuchithwa kokushisa okuphezulu kunciphisa ukuguga kwamathuluzi kanye nokuguqulwa kwe-thermal ngesikhathi sokusika ngesivinini esikhulu.

I-Isotropic Behavior: Izakhiwo ezifanayo zemishini kuzo zonke izinkomba, iqinisekisa imiphumela engaguquki yomshini.

b. Ukusebenza Kwemishini & Ukusebenza Kwezindleko

Isivinini Sokusika Esiphezulu: I-Aluminium ivumela amazinga okuphakelayo afika ku-5000 mm/min (kuye nge-alloy), enciphisa izikhathi zomjikelezo.

Ukuvumelana Kwamathuluzi: Ihambisana ne-carbide, i-HSS, namathuluzi e-PCD, enikeza ukuguquguquka kokusebenza kanzima nokuqeda.

Ukulawulwa kwe-Chip: Ama-alloys akhiwe njenge-6061 akhiqiza ama-chips aqhubekayo, kuyilapho amamaki e-free-machining (isb, 6061 ane-Pb/Bi eyengeziwe) akhiqiza ama-chips aphukayo omshini ozenzakalelayo.

c. Ukuguquguquka Kwangemva Kokucubungula

Ukuqedwa kwendawo: I-anodizing, i-powder coating, i-electroplating, noma ukuqhunyiswa kobuhlalu ukuze kuthuthukiswe ubuhle nokumelana nokugqwala.

Ukwelashwa Kokushisa: Ukushisa ngokwezifiso (isb, i-T6) ukuze kuzuzwe ubulukhuni obuqondiwe kanye nokukhululeka kwengcindezi ngemva komshini.

3. I-CNC Machining Solutions ye-Aluminium ye-Shanghai Miandi

Sebenzisa amandla ethu okuphela-kuya-ekupheleni ukuguqula ama-alloys e-aluminium abe izingxenye ezinembayo:

a. Ukunikezwa Kwempahla

Uchungechunge olugcwele lwengxubevange ye-aluminium: 6061, 7075, 2024, 5052 kumapuleti, izinduku, amashubhu, nama-extrusions angokwezifiso, athathwe ezigayweni eziqinisekisiwe.

Izinketho Zokushisa: Okufakiwe (O), ukwelashwa ngesixazululo (T4), ubudala (T6), kanye nokunciphisa ukucindezeleka (T651) ukuze kuhlangatshezwane nezidingo zomshini nokusebenza.

b. Izinsizakalo ze-CNC ezinembile

Amakhono Omshini:

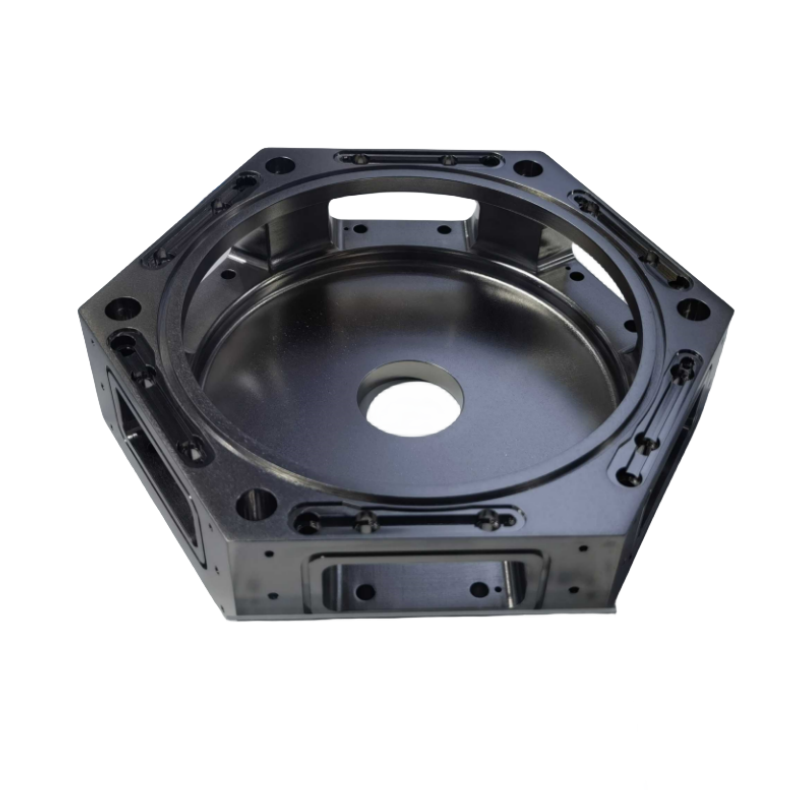

3/4/5-axis CNC milling yamajiyometri ayinkimbinkimbi (isb, abakaki be-aerospace, amathuluzi ezokwelapha).

Ukujika kwe-CNC kwamashafti, amahabhu, nezingxenye eziyisilinda (ukubekezela: ±0.005 mm).

Imishini yaseSwitzerland yezingxenye zokunemba okuncane (ububanzi: 0.5-20 mm).

Inqubo yokusiza: Ukubhoboza, ukuthepha, ukuthunga, ukuphequlula, kanye ne-EDM ngezici eziyinkimbinkimbi.

c. Ukuqinisekisa ikhwalithi

I-ISO 9001:2015 Iqinisekisiwe: Ukuhlolwa okuqinile kwekhemikhali yezinto ezibonakalayo, izakhiwo zemishini, nokunemba kobukhulu (i-CMM/isilinganiso sokubonwa).

Ukusekelwa kwe-DFM: Ukubonisana kwamahhala kokuklama komshini ukuze kuthuthukiswe ingxenye yejometri ngezindleko nokusebenza kahle.

d. Ukwenza ngokwezifiso & Scalability

Isampula yeqoqo elincane ekukhiqizweni kwevolumu ephezulu, nokuguqulwa ngokushesha (izinsuku eziyi-7-10 zama-prototypes).

Ukuthobela imboni: Izinto ezisetshenziswayo ezigunyazwe kumazinga e-ASTM, AMS, GB, noma ISO, anemibhalo yokulandeleka yamaklayenti omkhathi nezimoto.

4. Kungani Khetha Aluminium for CNC Machining?

Ibhalansi Yamandla Esisindo: Ilungele izinhlelo zokusebenza lapho idizayini engasindi ibalulekile (isb., i-aerospace, ama-drones).

Izindleko: Izindleko eziphansi zempahla nemishini kune-titanium noma insimbi, ekwazi ukuphinda isetshenziswe kahle kakhulu.

Inkululeko Yokuklama: Izimo eziyinkimbinkimbi, izindonga ezincane, nokubekezelelana okuqinile okufinyeleleka ngemishini yesimanje ye-CNC.

Xhumana ne-Shanghai Miandi Namuhla ukuze ulungiselelweCNC machining izixazululo usebenzisa premium aluminium alloys. Kungakhathaliseki ukuthi udinga i-prototype eyodwa noma izingxenye ezikhiqizwe ngobuningi, ubuchwepheshe bethu ekukhetheni ingxubevange, ukunemba komshini, nokulawula ikhwalithi kuqinisekisa ukuthi iphrojekthi yakho iyaphumelela.

I-Shanghai Miandi Metal Products Co., Ltd. - Ukunemba kukho Konke Ukusika.

Isikhathi sokuthumela: Jun-12-2025