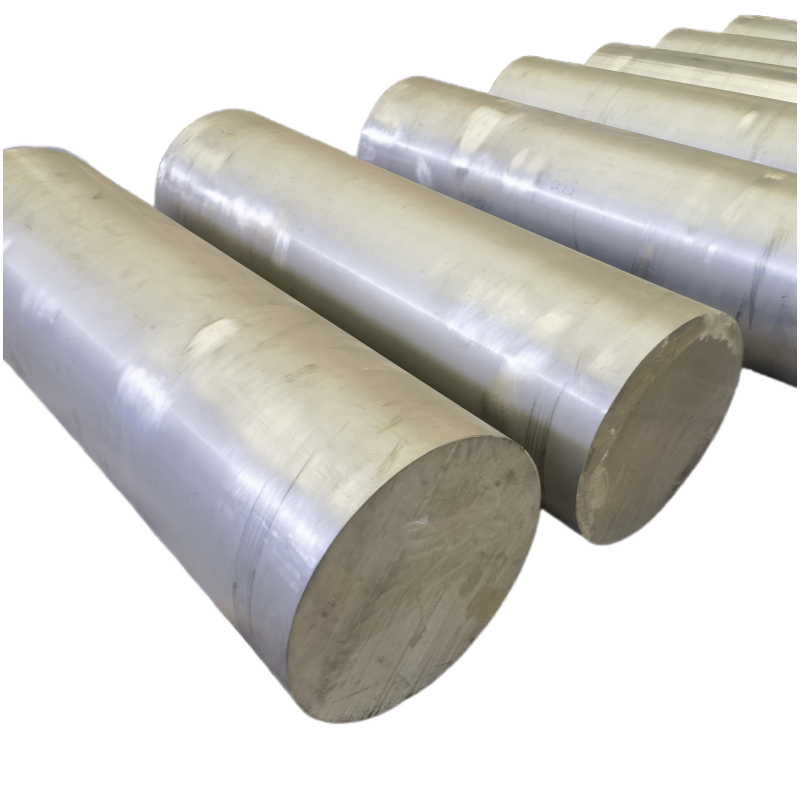

Endaweni yama-alloys e-aluminium esebenza kahle kakhulu,7075 T652 imigoqo ye-aluminium eyakhiwezigqame njengebenchmark yamandla, ukuqina, kanye nokuzinza kohlangothi, okuzenza zibe izinto ezikhethwayo ezimbonini lapho "isisindo esincane kodwa esiqinile" kungesona nje isidingo, kodwa umshayeli obalulekile wokusebenza kahle. Ngokungafani namamaki e-aluminium ajwayelekile, i-7075 T652 ingena ngenqubo enembile yokubumba okushisayo ehlanganiswe nokwelashwa kokushisa kwe-T652 (isixazululo se-annealing, quenching, kanye nokuguga okwenziwa emazingeni okushisa alawulwayo), okuholela kwinto eqeda ukukhubazeka kwangaphakathi, ecwenga ukwakheka kokusanhlamvu, futhi ivule izakhiwo zemishini ezihlukile. Kubakhiqizi bobunjiniyela be-aerospace, izimoto, kanye nobunjiniyela obunembayo, le ngxubevange ivala igebe phakathi kokuthembeka kwempahla eluhlaza kanye nokusebenza komkhiqizo wokugcina, kubhekwana namaphuzu obuhlungu ayinhloko njengokwehluleka kwengxenye ngaphansi kokucindezeleka okukhulu, ukungasebenzi kahle kwamandla okuhlobene nesisindo, kanye nezindinganiso eziqinile zokuthobela imboni.

1. Ukwakheka Kwamakhemikhali: Isisekelo Sokusebenza Okuphakeme

Izici ezihlukile zamabha e-aluminium engu-7075 T652 akhiwe asekelwe ekwakhekeni kwamakhemikhali alinganiswe ngokucophelela, lapho i-alloying ngayinye idlala indima eqondiwe ekuthuthukiseni amandla, ukumelana nokugqwala, kanye nokusebenza kahle. Njengelungu le-7000 yochungechunge lwe-aluminium alloys (i-zinc-magnesium-copper alloys), ukwakheka kwayo kunamathela kumazinga aqinile we-ASTM B211 kanye ne-EN 573-3, iqinisekisa ukuvumelana kulo lonke iqoqo, into engaxoxiswana ngayo ezimbonini ezingakubekezeleli nhlobo ukuhlukahluka kwempahla.

Izakhi ezinkulu ze-alloying ziwumgogodla wokusebenza kwayo:

I-Zinc (Zn): 5.1% ~ 6.1%. Isici esiyinhloko sokuthuthukisa amandla. I-Zinc yenza inhlanganisela ye-intermetallic (isb, i-MgZn₂) ngesikhathi sokwelashwa kokushisa, okwenza isiginesha yengxubevange ibe namandla aqine kakhulu ngenxa yokuqina kwezulu.

I-Magnesium (Mg): 2.1% ~ 2.9%. Isebenza ngokuvumelana ne-zinc ukuze ikhulise ukuqina kwemvula. Ngokuphromotha ukwakheka okuhle, ukushona okufanayo ku-aluminium matrix, i-magnesium ikhulisa kokubili amandla nokumelana nokukhathala, okubalulekile ezingxenyeni ezingaphansi kwemithwalo ephindaphindiwe.

- Ithusi (Cu): 1.2%~2.0%. Akuthuthukisi amandla kuphela kodwa futhi nokusetshenziswa kwemishini kanye nokuqina kwe-stress corrosion cracking (SCC). I-Copper ishintsha ukwakheka kwezigaba ze-intermetallic, inciphisa ukuhwalala futhi ithuthukise impendulo ye-alloy emisebenzini yomshini wokunemba njengokugaya nokubhoboza.

Izinto zokulandela umkhondo nokungcola kulawulwa ngokuqinile ukuze kugwenywe ukuwohloka kokusebenza:

- I-Chromium (Cr): 0.18%~0.28%. Isebenza njengesicwengisisi sokusanhlamvu, inciphisa ukukhula okusanhlamvu ngesikhathi sokubumba nokwelashwa kokushisa. Lokhu kubangela ukwakheka kwe-microstructure okufanayo, okuhumusheka ezicini ezingaguquki zemishini kuyo yonke ibha.

- Insimbi (Fe) & Silicon (Si): ≤0.50% ngayinye. Kuncishiswe njengokungcola, njengoba amaleveli eqile angakha izinhlayiya ezimahhadla ze-intermetallic (isb, i-Al₃Fe) ezenza buthaka ingxubevange futhi zehlise ukudumba.

- I-Manganese (Mn), i-Titanium (Ti), kanye Nezinye Izinto: ≤0.30% inani. Ingezwe ngamanani amancane ukuze kuqhutshekwe kuzinziswe i-matrix futhi kuthuthukiswe ukuzinza kwe-thermal, iqinisekisa ukuthi ingxubevange igcina izici zayo ngisho nasezimweni zokushisa ezimaphakathi.

2. Ukusebenza Okuphelele: Lapho Amandla Ehlangana Nokuguquguquka

7075 T652 iphrofayili yokusebenza kwamabha e-aluminium enziwe mbumbulu iyisigaba sobuciko sokulinganisa izimfuno zezinto ezibonakalayo ezingqubuzanayo, enikeza amandla aphezulu ensimbi, inzuzo engasindi ye-aluminium, kanye nokucutshungulwa kwama-alloys athambile kakhulu. Ukusebenza kwayo akukhona nje "okuhlaba umxhwele" ekuhlolweni kwelebhu; yakhelwe ukumelana nezingcindezi zomhlaba wangempela, kusukela ekucindezelweni okwedlulele ezingxenyeni ze-aerospace kuya ekudlidlizeni okuqhubekayo ezingxenyeni zezimoto.

Ukusebenza Kwemishini: Amandla Ahamba phambili Embonini

Ngemuva kokwelashwa kokushisa kwe-T652 (kuxazululwe ku-460 ° C ~ 480 ° C, kucinywe emanzini, futhi kukhulile ngokuzenzela ku-120 ° C ~ 130 ° C amahora angu-24), ingxubevange izuza izakhiwo zemishini ezedlula izinsimbi eziningi ezingenayo insimbi:

- Amandla Okuqina (σb): ≥510 MPa. Idlula lokho kwezinsimbi eziningi ezinekhabhoni ephansi kuyilapho inesisindo esingu-1/3 kuphela, okuyenza ilungele izakhiwo ezizwelayo isisindo.

- Amandla Esivuno (σ0.2): ≥470 MPa. Iqinisekisa ukuthi izingxenye zimelana nokuguqulwa okuhlala njalo ngisho nangaphansi kwemithwalo ephezulu emile noma eguquguqukayo, njengegiya lokuhlala endizeni noma imiphini yemishini yezimboni.

- I-Elongation at Break (δ): ≥8% Imethrikhi ebalulekile yokuqina; ngokungafani nama-alloys anamandla aphezulu, i-7075 T652 igcina i-ductility eyanele ukuze imunce amandla omthelela, inciphisa ingozi yokwehluleka kungazelelwe.

- Amandla Okukhathala (imijikelezo engu-10⁷): ≥150 MPa Ibalulekile ezingxenyeni ezingaphansi kwengcindezi ephindaphindiwe, njengezingxenye ezimisiwe zezimoto noma ama-shaft ajikelezayo, lapho ukuqhekeka kokukhathala kuyimodi yokwehluleka evamile.

Ukusebenza Komzimba Nokwemvelo

Ngalé kwamandla emishini, izakhiwo zomzimba zengxubevange zithuthukisa ukusebenza kwayo ezinhlotsheni ezihlukahlukene:

- Ukuminyana: 2.81 g/cm³ 35% ilula kunensimbi (7.85 g/cm³) kanye no-10% ilula kune-titanium (4.51 g/cm³), kunciphisa ngokuqondile ukusetshenziswa kukaphethiloli ezinsizeni zezimoto/ze-aerospace kanye nokwenza lula ukufakwa emishinini emikhulu.

- I-Thermal Conductivity: 130 W/(m·K) Iphansi kune-aluminium emsulwa (237 W/(m·K)) kodwa yanele ukukhipha ukushisa ezingxenyeni ezifana nezivalo zikagesi noma izingxenye zenjini, ezivimbela ukushisa ngokweqile.

- Ukumelana Nokugqwala: Kuphakathi kuya phezulu. Uma ibhangqwe nokwelapha okungaphezulu (isb., i-anodizing, ukuguqulwa kwe-chromate), imelana ne-oxidation nokuhlaselwa kwamakhemikhali ezindaweni ezinokhahlo, ezifana nezilungiselelo zasolwandle noma zezimboni. Ngokungafani ne-7075 engelashiwe, i-T652 temper inciphisa i-SCC, inzuzo eyinhloko ngaphezu kwamanye amabanga aphezulu e-aluminium.

Ukusebenza Kokucubungula: Kujwayelana Nokukhiqiza Okunembayo

Ukuqamba akuyona nje ainqubo yokubumba ye-7075 T652. Kuyindlela yokuthuthukisa ukusebenza kahle. Inqubo yokubumba eshisayo (imvamisa ku-350–450°C) iqondanisa ukwakheka kwezinhlamvu zengxubevange nesiqondiso sokucindezeleka, ithuthukisa amandla ezimbazoni ezithwala imithwalo. Ukwengeza:

- Ukusebenziseka: Kuhle kakhulu. Okuqukethwe kwethusi kunciphisa ukuguga kwamathuluzi, okuvumela ukubekezelelana okuqinile (kufika ku-±0.005 mm) emisebenzini yomshini wokunemba. Lokhu kubalulekile ezingxenyeni ezinjengama-hydraulic valves noma izixhumi ze-aerospace, lapho ukunemba kobukhulu kungaxoxiswana khona.

- Ukushisela: Kuyalawulwa. Nakuba ingashiseki njenge-aluminium engu-6061, ingashiselwa kusetshenziswa amasu akhethekile (isb., ukushisela i-friction stir) ngokwelashwa kokushisa kwangaphambi nangemuva kokushisela, kunwetshwe ukusetshenziswa kwayo kuzakhiwo ezinkulu, ezishiselwe.

- Ukuhleleka: Kulingene. Amabha afojiwe agcina i-ductility eyanele yezinqubo zokwakheka kwesibili njengokugoba noma ukukhishwa, okuwenza avumelane nemiklamo yengxenye yangokwezifiso.

3. Ububanzi Bokusebenza: I-Powering High Demand Industries

Inhlanganisela eyingqayizivele ye-7075 T652 ye-aluminium bar 'yamandla eyingqayizivele, engasindi, kanye nokucutshungulwa kwayo iwenza abaluleke kakhulu ezimbonini lapho ukwehluleka kubiza khona, nokusebenza kahle kubaluleke kakhulu. Ngezansi kunezindawo zayo eziyinhloko zohlelo lokusebenza, ngayinye eboshelwe ngqo kuzinzuzo zayo zokusebenza:

I-Aerospace & Defense

Imboni ye-aerospace iyona eyamukela kakhulu i-7075 T652, ngenxa yokuthobela kwayo izindinganiso ze-aerospace (isb, i-AMS 4343). Izinhlelo zokusebenza ezibalulekile zifaka:

- Izingxenye Zesakhiwo Sendiza: Ama-wing spars, amafreyimu e-fuselage, kanye nezingxenye zegiye lokuhlala lapho isilinganiso salo samandla aphezulu nesisindo sinciphisa isisindo sendiza (futhi ngaleyo ndlela izindleko zikaphethiloli) ngenkathi ihlangabezana nezimfuneko zokuphepha ze-FAA.

- Izimpahla Zokuzivikela: Amapuleti ezikhali zezimoto zempi nezingxenye zesakhiwo zama-drones lapho ukumelana kwawo komthelela kanye nomklamo ongasindi kuthuthukisa ukuhamba ngaphandle kokubeka engcupheni ukuvikela.

Ezezimoto (Ezisebenza Kakhulu Nezimoto zikagesi)

Ekushintsheni ezimotweni zikagesi (ama-EV) kanye nezimoto zomjaho ezisebenza kahle kakhulu, ukwehlisa isisindo kubalulekile ukuze kunwetshwe ububanzi bebhethri nokuthuthukisa ukuphatha. I-7075 T652 isetshenziselwa:

- Izingxenye ze-EV Powertrain: Amashafu ezimoto nezivalo zebhethri lapho amandla ayo avikela izinto zikagesi ezizwelayo, futhi ukwakheka kwayo okungasindi kwehlisa isisindo sisonke semoto.

- Izingxenye Zemoto Yomjaho: Izingalo ezimisiwe, izinsimbi zokuqondisa, namabhuleki ama-brake caliper lapho ukumelana kwayo nokukhathala imelana nengcindezi eyedlulele yokushayela ngesivinini esiphezulu, futhi ukusebenziseka kwayo kuvumela imiklamo ye-aerodynamic, ngokwezifiso.

Imishini Yezimboni Nobunjiniyela Bokunemba

Emishini yezimboni esebenza ngaphansi kwengcindezi eqhubekayo noma edinga ukubekezelelana okuqinile, i-7075 T652 iletha ukwethembeka:

- Imishini Enzima: Izinti ze-hydraulic cylinder kanye nezingxenye ze-crane lapho amandla ayo okukhiqiza okuphezulu amelana nokugoba ngaphansi kwemithwalo esindayo, futhi ukumelana kwayo nokugqwala kumelana nezindawo zangaphandle noma zezimboni.

- Amathuluzi Anembile: Ama-spindle amathuluzi omshini nezingalo zerobhothi lapho ukuzinza kwawo kobukhulu (i-coefficient ephansi yokwandisa ukufudumala: 23.6 μm/(m·K)) kuqinisekisa ukusebenza okungaguquguquki ngisho nangesikhathi sokukhiqiza okude.

I-Marine & Offshore

Nakuba i-aluminiyamu ngokuvamile ingeyona inketho yokuqala yezicelo zasolwandle, i-7075 T652 (enokwelashwa okungaphezulu kwendawo) ihamba phambili kulokhu:

- I-Hardware Yasolwandle: Amashafu ophephela wesikebhe kanye nezingxenye zokubopha lapho idizayini yayo engasindi yenza lula ukufakwa, futhi ukumelana nokugqwala kwayo (uma i-anodized) imelana nokuchayeka emanzini anosawoti.

Uzakwethu Uzakwethu nge-Premium 7075 T652 Amabha E-Aluminium Yakhiwe

Sisebenza ngokukhethekile ekukhiqizeni7075 T652 imigoqo ye-aluminium eyakhiweezihlangabezana nezindinganiso zomkhakha eziqinile ukusuka ku-ASTM kuye ku-AMS. Inqubo yethu yokwenza izinto isebenzisa okokusebenza kwesimanje ukuze kuqinisekiswe ukwakheka okusanhlamvu okufanayo, futhi iqoqo ngalinye lihlolwa ngokuqinile (ukuhlolwa okuqinile, ukuhlolwa kokuqina, nokuhlaziywa kokwakheka kwamakhemikhali) ukuze kuqinisekiswe ukusebenza ngendlela efanayo. Kungakhathaliseki ukuthi udinga ubude obungokwezifiso, ububanzi, noma ukwelashwa kwendawo (i-anodizing, i-powder coating), ithimba lethu lonjiniyela lisebenza nawe ukuletha izixazululo ezihambisana nesicelo sakho.

Kubakhiqizi be-aerospace, bezimoto, noma bezimboni abafuna isisombululo se-aluminum esinamandla amakhulu, esingasindi, amabha e-aluminium engu-7075 T652 ayimpendulo. Xhumana nathi namuhla ukuze ucele imininingwane yobuchwepheshe

Isikhathi sokuthumela: Nov-17-2025