I-1060 Aluminium Alloy Plate Corrosion Resistance aluminium Sheet 1060

I-Aluminium / Aluminium 1060 ingxubevange ingamandla aphansi kanye nengxube ye-Aluminium / Aluminium ehlanzekile enesici esihle sokumelana nokugqwala.

I-Aluminium / Aluminium 1060 ingxubevange ingenziwa lukhuni kuphela ekusebenzeni okubandayo. I-Tempers H18, H16, H14 ne-H12 inqunywa ngokusekelwe enanini lokusebenza okubandayo okunikezwa kule alloy.

I-Aluminium / Aluminium 1060 ingxubevange ikalwe ngokungenzeleli kuya kokubi, ikakhulukazi ezimeni ezithambile. I-machinability ithuthukiswa kakhulu ekuthukutheleni okunzima (okubandayo). Ukusetshenziswa kwamafutha kanye nensimbi yesivinini esikhulu noma i-carbide kuyanconywa kule alloy. Okunye ukusika le alloy kungenziwa futhi yomile.

I-Aluminium / Aluminium 1060 ingxubevange isetshenziswa kabanzi ekwenzeni izimoto zamathangi kaloliwe kanye nemishini yamakhemikhali.

| I-Chemical Composition WT(%) | |||||||||

| I-silicon | Insimbi | Ithusi | Magnesium | IManganese | I-Chromium | Zinc | I-Titanium | Abanye | I-Aluminium |

| 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | 99.6 |

| Izakhiwo Zemishini Ejwayelekile | ||||

| Ulaka | Ubukhulu (mm) | Amandla Okuqina (Mpa) | Isivuno Amandla (Mpa) | Ukwelula (%) |

| H112 | 4.5 ~ 6.00 | ≥75 | - | ≥10 |

| 6.00 ~ 12.50 | ≥75 | ≥10 | ||

| 12.50 ~ 40.00 | ≥70 | ≥18 | ||

| >40.00–80.00 | ≥60 | ≥22 | ||

| H14 | 0.20 ~ 0.30 | 95 ~ 135 | ≥70 | ≥1 |

| >0.30–0.50 | ≥2 | |||

| ~0.50~0.80 | ≥2 | |||

| ~0.80~1.50 | ≥4 | |||

| 1.50 ~ 3.00 | ≥6 | |||

| 3.00 ~ 6.00 | ≥10 | |||

Izinhlelo zokusebenza

Inzuzo Yethu

Inventory and Delivery

Sinomkhiqizo owanele esitokweni, singanikela ngezinto ezanele kumakhasimende. Isikhathi sokuhola singaba phakathi kwezinsuku eziyi-7 zezinto zesitoko.

Ikhwalithi

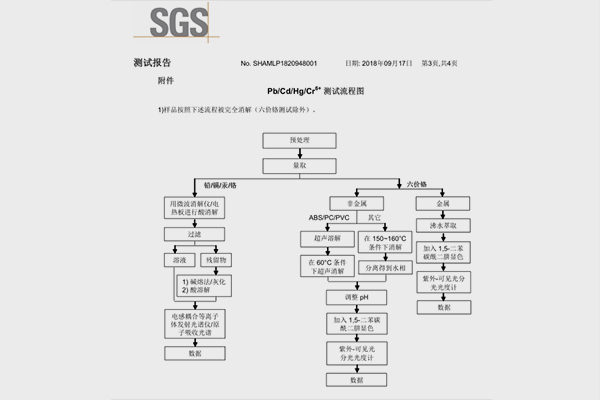

Yonke imikhiqizo ivela kumkhiqizi omkhulu, singakunikeza i-MTC. Futhi singanikeza umbiko wokuhlola Wenkampani Yangaphandle.

Ngokwezifiso

Sinomshini wokusika, usayizi wangokwezifiso uyatholakala.