I-Aluminium WaloysDlala indima ebalulekileyo kumzi mveliso we-semicondcuctor, ngezicelo zazo ezibanzi ezinefuthe elinzulu. Nasi isishwankathelo sendlela i-alminuum ye-alloys inefuthe kwishishini le-semicondcuctor kunye nezicelo zabo:

I. Izicelo zeI-Aluminium Waloyskwi-semicondcuction imveliso

I-1. Izinto zesakhiwo zezixhobo:

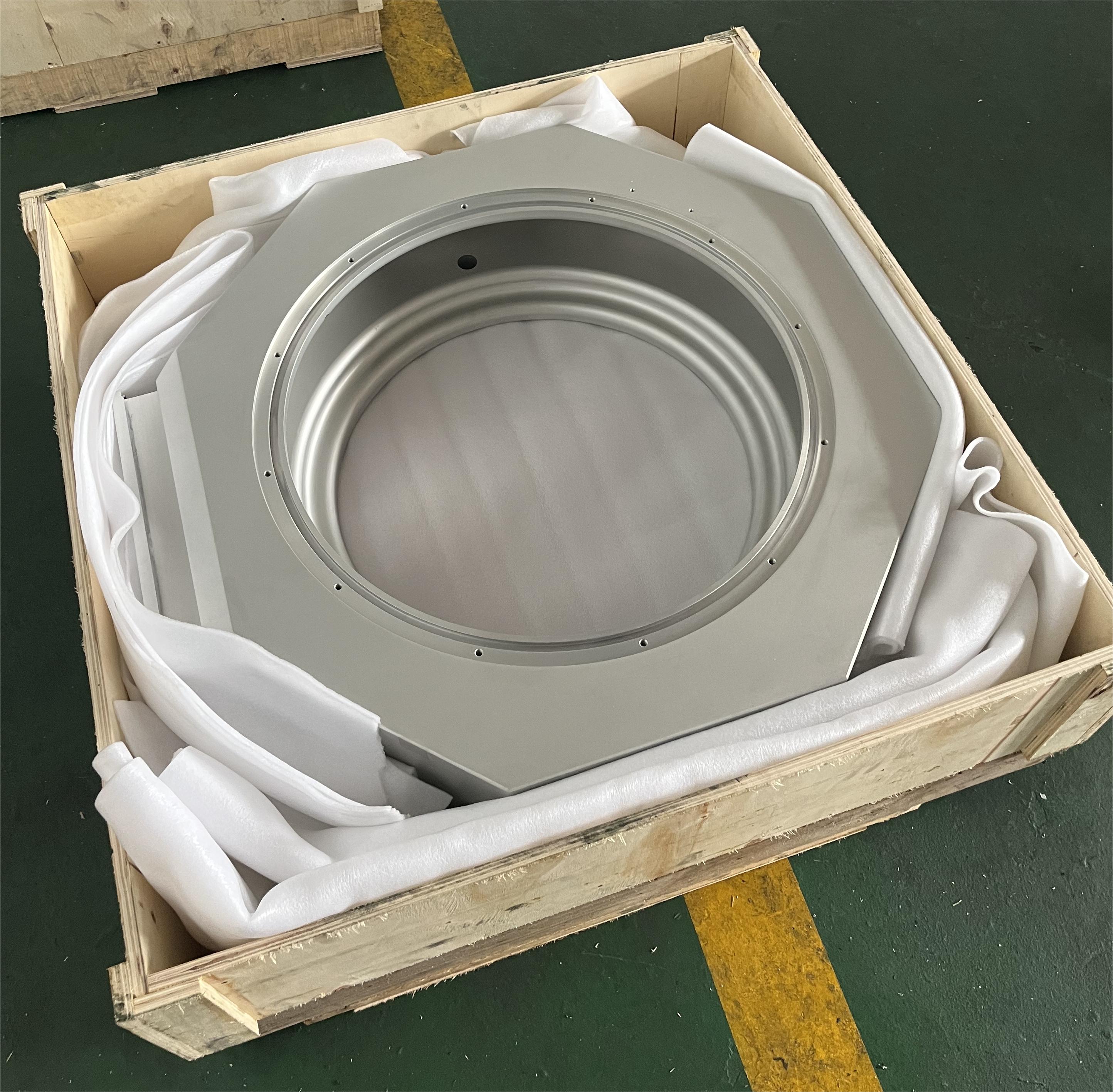

-I-vacuum ye-vacuum: I-Aluminium Alfs zisetyenziselwa ukwenza amagumbi e-vacuum kwizixhobo ze-semicondcuctor ngenxa yeepropathi zabo ezilungileyo kakhulu kunye nokuphumeza kwengqondo. La magumbi kufuneka akwazi ukumelana nobushushu obuphakamileyo kunye noxinzelelo ngelixa ugcina indawo ephezulu yevacunuum.

-Inkxaso kunye neefreyimu **: I-Aluminium Alloys, ukuba i-Aluminium ye-Allows, isetyenziswa kakhulu ukwenza inkxaso kunye neefreyimu zezixhobo, ukunciphisa ukuguquguquka okusebenzayo.

I-2. Izinto zokuSebenzisa ubushushu:

-Ubushushu obushushu: I-Aluminium Alloys, eyaziwa ngokuba yinkqubo yokuqhutywa komhlaba, isetyenziselwa ukwenza ubushushu kwizixhobo ze-semicondcuctor, ukunceda ukwahlula-hlula ubushushu bezixhobo.

-Iipleyiti zokupholisa: Iipleyiti zokupholisa i-Aluminium Alting zisetyenziswa kwiinkqubo zokupholisa kwezixhobo ze-semicondcucres zokwenza amaqondo obushushu asezantsi, ekwandiseni ukuthembeka kunye ne-wospan yeemveliso.

I-3. Izixhobo zokuphatha ngesandla:

-Ingalo zerobhothi: Iingalo zerobhothi ezisetyenziselwa ukudlulisela i-wafs ngexesha lokuvelisa i-semicondcucy kuhlala kwenziwa ngeendlela ze-Aluminium. Ipropathi ekhanyayo kunye neendawo eziphakamileyo ze-Aluminium ze-allows zenza ukhetho olufanelekileyo, ukuqinisekisa ukuhamba ngokuthe ngqo kunye nokufikelwa ngokukhawuleza.

II. Izicelo zealuminium zals kwizixhobo ze-semicondcuctor

I-1. Iincoko zentsimbi:

- I-Aluminium Complonclicts: I-Aluminium kunye ne-alloys yayo isetyenziswe ngokubanzi njengezixhobo ezinxibelelana ngeetshiphu. Ngaphandle kweentetho zobhedu ngokuthe chu ukutshintsha i-Alminum kwiminyaka yakutshanje, i-aluminium ihlala ibalulekile kwizicelo ezithile ngenxa yokuqhuba kakuhle kunye nokusebenza kweendleko.

2. Izinto zokupakisha:

Iphakheji ye-Aluminium ye-Aluminium: I-Aluminium Altings isetyenziswa kwi-semiconductor yesixhobo sokubonelela ngonxibelelwano lombane olusebenzayo kunye nokukhuselwa koomatshini ngelixa ubonelela ngokusebenza kakuhle ukuqinisekisa ukuthembeka kwezixhobo ngexesha lokusebenza kakuhle.

III. IINGXAKI ZOLWAZI LAMALUMUM KWI-Semiconductor

1. Isibane esikhanyayo kunye namandla aphezulu:

-Indlela elula ye-allomium

2. Ukuqhutywa kwengqondo okuhle:

-Ukugqibelela kwabo okuhle kwenza ukuba izabelo ze-aluminium zenza kakuhle kwizicelo zokusebenzela ubushushu, ukuqinisekisa ngezixhobo ze-semicondtor ezigcina amaqondo obushushu aphezulu ngexesha lokusebenza kakuhle.

I-3. Okwenzini olungileyo:

- I-Alumnom ye-Aluminium ilula kumatshini kunye nefom, ihlangabezane neemfuno zokulungisa izinto ze-semicondcuctor kunye nezinto.

I-4. Ukunganyangeki kwe-Corrosion:

-Ukuxhathisa i-corrosion ye-Aluminium ibanika ixesha elide lokuphila kwiindawo ezinobunzima bemveliso ye-semicondcuction, ukunciphisa isantya sokulungiswa kwezixhobo kunye nokutshintshwa.

Iv. Amathemba exesha elizayo

1. Uphuculo lwezinto ezibonakalayo:

-Ukuqhubela phambili kwetekhnoloji ye-semicondcuctor, iimfuno zomsebenzi zezinto zokwakha ziyaqhubeka. Ukuqulunqwa kunye nokulungiswa kwe-alloum alloys kuya kuphuculwa rhoqo ukuphumelela ukuqhubela phambili, ukuqhutywa kwe-thermas, kunye namatshini woomatshini.

2. Ukuphuhliswa kwezicelo ezitsha:

-Itekhnoloji ekhulayo ye-semicondcuct (efana nekhomputha yekhomputha kunye ne-elektroniki eguqukayo) inokuzisa iimfuno ezintsha ze-Aluminium Alloy. Uphando kunye nophuhliso lwezixhobo ezintsha ze-aluminium kunye nezicelo ziya kuba licala elibalulekileyo kwixesha elizayo.

I-3. Ukukhusela okusingqongileyo kunye nokuzinza:

-Umsebenzi wokuphinda usebenzise kwakhona kunye nokwenza kwakhona iimpawu ze-alloum Alloys zinika izibonelelo kubuKhuselo lwendalo kunye nokuzinza. Kwixa elizayo, ishishini le-semicondcuctor liya kugxininiswa ngakumbi kwimpembelelo yokuphinda isebenze kunye nefuthe lokusingqongileyo, ukukhuthaza ukusetyenziswa kunye nophuhliso lwee-allomim zals.

Isishwankathelo,I-Aluminium WaloysYiba nefuthe elibonakalayo kumzi mveliso we-semicondcuctor, udlale indima ephambili kwizixhobo zokwenziwa kwezixhobo, izicelo ezibonakalayo, kunye nophuhliso lwetekhnoloji. Njengoko itekhnoloji iqhubeka kwaye ifuna utshintsho, usetyenziso lwealuminum alloys kwishishini le-semicondcuctor iya kuqhubeka nokwandisa kwaye inzulu.

Ixesha lasemva: jul-05-2024