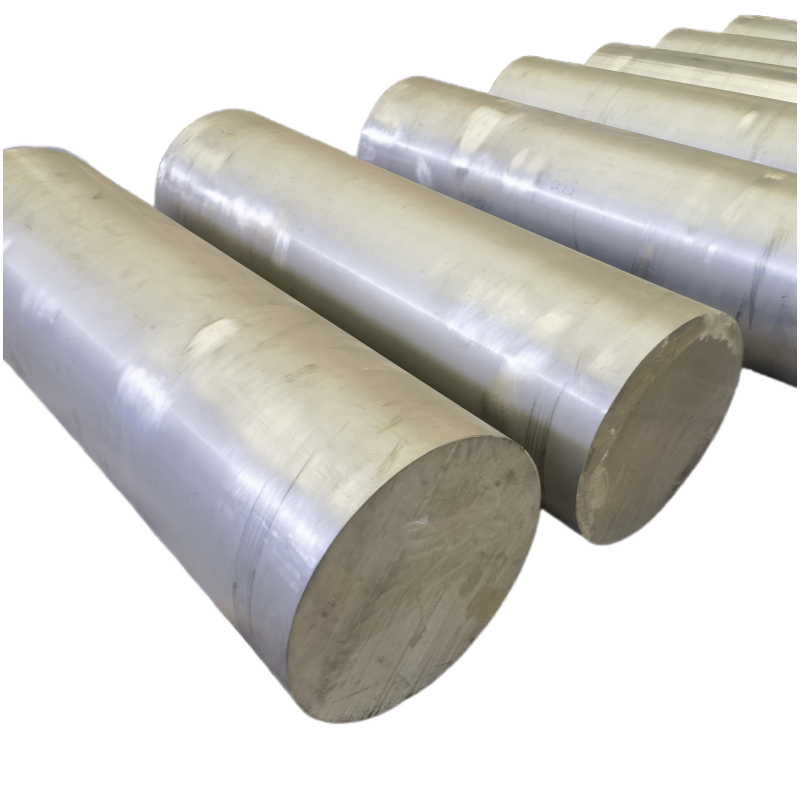

Sebakeng sa lisebelisoa tse phahameng tsa aluminium tse sebetsang hantle,7075 T652 e entsoeng ka aluminium mekoalloe hlahella e le sesupo sa matla, ho tšoarella, le botsitso bo boholo, e leng se etsang hore e be lisebelisoa tsa khetho bakeng sa liindasteri moo "boima bo bobebe empa bo le matla" e seng tlhoko feela, empa ke mokhanni oa bohlokoa oa ts'ebetso e sebetsang hantle. Ho fapana le limaraka tse tloaelehileng tsa aluminium, 7075 T652 e etsoa ka mokhoa o nepahetseng oa ho chesa o kopantsoeng le phekolo ea mocheso oa T652 (tharollo annealing, quenching, le botsofali ba maiketsetso ka mocheso o laoloang), ho fella ka boitsebiso bo felisang bofokoli ba ka hare, bo hloekisang sebopeho sa lijo-thollo, le ho notlolla thepa e ikhethang ea mochine. Bakeng sa bahlahisi ba boenjiniere ba sefofane, likoloi le boenjiniere bo nepahetseng, motsoako ona o koala lekhalo pakeng tsa ho tšepahala ha thepa e tala le ts'ebetso ea sehlahisoa sa ho qetela, ho sebetsana le lintlha tse bohloko tsa mantlha tse kang ho hlōleha ha karolo tlas'a khatello e matla, ho se sebetse ha matla a amanang le boima ba 'mele, le litekanyetso tse tiileng tsa ho latela indasteri.

1. Sebopeho sa Lik'hemik'hale: Motheo oa Ts'ebetso e Phahameng

Litšobotsi tse ikhethang tsa 7075 T652 li-aluminium tse entsoeng ka maiketsetso li thehiloe ka har'a sebopeho sa eona sa lik'hemik'hale tse lekantsoeng ka hloko, moo karolo e 'ngoe le e 'ngoe ea motsoako e bapalang karolo e lebisitsoeng ho matlafatsa matla, ho hanyetsa kutu le ts'ebetso. Joaloka setho sa 7000 letoto la li-alloys tsa aluminium (zinc-magnesium-copper alloys), sebopeho sa eona se latela litekanyetso tse thata tsa ASTM B211 le EN 573-3, ho netefatsa botsitso ho sehlopha se seng le se seng, e leng ntho e ke keng ea buisanoa bakeng sa liindasteri tse nang le mamello ea zero bakeng sa phapang ea lintho tse bonahalang.

Lintlha tse ka sehloohong tsa alloying ke mokokotlo oa ts'ebetso ea eona:

- Zinc (Zn): 5.1% ~ 6.1%. Ntho ea mantlha e matlafatsang matla. Zinc e etsa metsoako ea li-intermetallic (mohlala, MgZn₂) nakong ea phekolo ea mocheso, e nolofalletsang ho saena ha alloy matla a phahameng a matla ka ho thatafala ha pula.

- Magnesium (Mg): 2.1% ~ 2.9%. E sebetsa ka kopanelo le zinki ho holisa pula e thata. Ka ho khothalletsa ho thehoa ha metsi a hloekileng, a tšoanang le a aluminium matrix, magnesium e matlafatsa matla le ho hanyetsa mokhathala, e leng ea bohlokoa bakeng sa likarolo tse tlas'a meroalo e pheta-phetoang.

- Koporo (Cu): 1.2% ~ 2.0%. Ha e ntlafatse matla feela empa hape le machinability le stress corrosion cracking (SCC) ho hanyetsa. Koporo e fetola sebopeho sa mekhahlelo ea li-intermetallic, e fokotsa bofokoli le ho ntlafatsa karabelo ea alloy ts'ebetsong ea machining e nepahetseng joalo ka ho sila le ho cheka.

Lintlha tsa morao-rao le litšila li laoloa ka thata ho qoba ho senyeha ha ts'ebetso:

- Chromium (Cr): 0.18%~0.28%. E sebetsa joalo ka mohloekisi oa lijo-thollo, e fokotsa kholo ea lijo-thollo nakong ea ho foma le kalafo ea mocheso. Sena se etsa hore ho be le microstructure e ts'oanang haholoanyane, e fetolelang thepa e ts'oanang ea mochini ho pholletsa le bar eohle.

- Tšepe (Fe) & Silicon (Si): ≤0.50% ka 'ngoe. E fokotsoe e le litšila, kaha maemo a feteletseng a ka etsa likaroloana tse nyenyane tsa intermetallic (mohlala, Al₃Fe) tse fokolisang motsoako le ho fokotsa ductility.

- Manganese (Mn), Titanium (Ti), & Lintho tse ling: ≤0.30% kakaretso. E ekelitsoe ka bongata bo fokolang ho tsoela pele ho tsitsisa matrix le ho ntlafatsa botsitso ba mocheso, ho netefatsa hore motsoako o boloka thepa ea oona esita le libakeng tse itekanetseng tsa mocheso.

2. Ts'ebetso e Felletseng: Moo Matla a Kopanang le ho Fetoha

7075 T652 profil ea ts'ebetso ea li-aluminium tsa 7075 ke setsebi sa ho leka-lekanya litlhoko tsa thepa tse hanyetsanang, tse fanang ka matla a phahameng a tšepe, molemo o bobebe oa aluminium, le ts'ebetso ea lialloi tse bonolo haholoanyane. Ts'ebetso ea eona ha e "khahle" feela litekong tsa laborateng; e etselitsoe ho mamella khatello ea maikutlo ea lefatše la 'nete, ho tloha khatellong e feteletseng ea likarolo tsa sefofane ho isa ho thothomelo e sa khaotseng ea likarolo tsa likoloi.

Ts'ebetso ea Mechini: Matla a Eteletseng Pele ho Indasteri

Ka mor'a phekolo ea mocheso ea T652 (e rarollotsoeng ka 460 ° C ~ 480 ° C, e tingoa ka metsing, 'me e tsofetse ka 120 ° C ~ 130 ° C bakeng sa lihora tse 24), motsoako o finyella thepa ea mochine e fetang litšepe tse ngata tse se nang ferrous:

- Matla a Tensile (σb): ≥510 MPa. E feta litšepe tse ngata tsa khabone e tlase ha boima ba eona bo le 1/3 feela, e etsa hore e be e loketseng meaho e sa utloeng boima ba 'mele.

- Matla a ho Hlahisa (σ0.2): ≥470 MPa. E netefatsa likarolo tse hananang le deformation ea ka ho sa feleng leha e le ka tlas'a meroalo e phahameng e tsitsitseng kapa e matla, joalo ka lisebelisoa tsa ho lisa sefofane kapa li-shafts tsa mochini oa indasteri.

- Elongation at Break (δ): ≥8% Metric ea bohlokoa bakeng sa nako e telele; ho fapana le li-alloys tse matla tsa brittle, 7075 T652 e boloka ductility e lekaneng ho monya matla a matla, ho fokotsa kotsi ea ho hlōleha ka tšohanyetso.

- Matla a Mokhathala (10⁷ cycles): ≥150 MPa E bohlokoa bakeng sa likarolo tse tlas'a khatello ea maikutlo khafetsa, joalo ka likarolo tsa ho emisoa ha likoloi kapa li-shafts tse potolohang, moo mokhathala o phunyehang e leng mokhoa o tloaelehileng oa ho hlōleha.

Ts'ebetso ea 'Mele le ea Tikoloho

Ntle le matla a mochini, thepa ea 'mele ea alloy e ntlafatsa ts'ebetso ea eona lits'ebetsong tse fapaneng:

- Boima ba 'mele: 2.81 g/cm³ 35% e bobebe ho feta tšepe (7.85 g/cm³) le 10% e bobebe ho feta titanium (4.51 g/cm³), e fokotsang tšebeliso ea mafura ka kotloloho lits'ebetsong tsa likoloi/sefofane le ho nolofatsa ho kenya mochining o boima.

- Thermal Conductivity: 130 W / (m·K) Ka tlaase ho feta aluminium e hloekileng (237 W / (m·K)) empa e lekane bakeng sa ho qhala mocheso likarolong tse kang li-enclosures tsa elektronike kapa likarolo tsa enjene, ho thibela ho chesa haholo.

- Resistance ea Corrosion: E Itekanetse ho ea Holimo. Ha e kopantsoe le liphekolo tse holim'a metsi (mohlala, anodizing, chromate conversion), e hanana le tlhaselo ea oxidation le lik'hemik'hale libakeng tse thata, joalo ka maemo a leoatle kapa a indasteri. Ho fapana le 7075 e sa phekoloeng, bohale ba T652 bo fokotsa SCC, monyetla oa bohlokoa ho feta limaraka tse ling tse phahameng tsa aluminium.

Ts'ebetso ea Ts'ebetso: E Ikamahanya le Boemo ba Tlhahiso e nepahetseng

Forging hase feela amokhoa oa ho bopa bakeng sa 7075 T652. Ke mokhoa oa ho ntlafatsa ts'ebetso. Mokhoa oa ho chesa o chesang (ka tloaelo ho 350-450 ° C) o lumellana le sebopeho sa lijo-thollo tsa alloy le tataiso ea khatello ea kelello, ho matlafatsa matla ho lilepe tse boima tse jarang moroalo. Ho phaella moo:

- Boikemisetso: E ntle haholo. Litaba tsa koporo li fokotsa ho roala ha lisebelisoa, ho lumella ho mamellana ka thata (ho fihlela ho ± 0.005 mm) ts'ebetsong e nepahetseng ea machining. Sena se bohlokoa bakeng sa likarolo tse kang li-valve tsa hydraulic kapa li-fasteners tsa aerospace, moo ho nepahala ha dimensional ho ke keng ha buisanoa.

- Weldability: Laolwa. Le hoja e sa chesehe joaloka aluminium ea 6061, e ka chesetsoa ka mekhoa e khethehileng (mohlala, friction stir welding) ka phekolo ea mocheso pele ho nako ea morao-rao, ho atolosa tšebeliso ea eona meahong e meholo e cheselitsoeng.

- Formability: E itekanetseng. Li-bar tsa forged li boloka ductility e lekaneng bakeng sa lits'ebetso tsa bobeli tsa ho etsa joalo ka ho kobeha kapa extrusion, e li etsa hore li ikamahanye le meralo ea likarolo tsa moetlo.

3. Sebaka sa Kopo: Ho Matlafatsa Liindasteri tse Hlokang Holimo

7075 T652 "Motsoako o ikhethang oa li-aluminium tsa 7075 tsa matla, boima bo bobebe, le ts'ebetso ea ts'ebetso li li etsa tsa bohlokoa haholo indastering moo ho hloleha ho bitsang chelete e ngata, 'me ho sebetsa hantle ho le bohlokoa haholo. Ka tlase ke libaka tsa eona tsa mantlha tsa ts'ebeliso, e 'ngoe le e' ngoe e hokahane ka kotloloho le melemo ea eona ea ts'ebetso:

Sefofane le Tšireletso

Indasteri ea sepakapaka ke eona e amohelang 7075 T652 e kholo ka ho fetisisa, ka lebaka la ho latela maemo a sebaka sa sefofane (mohlala, AMS 4343). Lisebelisoa tsa bohlokoa li kenyelletsa:

- Likarolo tsa Sebopeho sa Lifofane: Li-spars tsa mapheo, liforeimi tsa fuselage, le lisebelisoa tsa lisebelisoa tsa ho lulisa moo matla a eona a holimo ho boima a fokotsa boima ba sefofane ('me kahoo litšenyehelo tsa mafura) ha li ntse li kopana le litlhoko tsa polokeho ea FAA.

- Thepa ea Tšireletso: Lipoleiti tsa lihlomo tsa likoloi tsa sesole le likarolo tsa sebopeho sa li-drones moo ho hanyetsa ha eona le moralo o bobebe o matlafatsang ho tsamaea ntle le ho senya ts'ireletso.

Likoloi (Ts'ebetso e Phahameng le Likoloi tsa Motlakase)

Ha re fetohela likoloing tsa motlakase (EVs) le likoloi tsa mabelo tse sebetsang hantle haholo, ho fokotsa boima ba 'mele ho bohlokoa bakeng sa ho lelefatsa lebelo la betri le ho ntlafatsa ts'ebetso. 7075 T652 e sebelisetsoa:

- Likarolo tsa EV Powertrain: Li-shaft tsa motor le li-betri tse koaletsoeng moo matla a eona a sireletsang lisebelisoa tsa elektroniki tse bobebe, 'me moralo oa eona o bobebe o fokotsa boima ba koloi ka kakaretso.

- Likarolo tsa Mabelo a Koloi: Matsoho a emisitsoeng, lithupa tsa seteraeke, le li-brake caliper moo mokhathala oa eona o mamellang khatello e matla ea ho khanna ka lebelo le holimo, 'me machano a eona a lumella meralo e tloaelehileng ea moea.

Mechini ea Liindasteri le Boenjiniere bo nepahetseng

Bakeng sa lisebelisoa tsa indasteri tse sebetsang tlas'a khatello ea maikutlo khafetsa kapa tse hlokang mamello e tiileng, 7075 T652 e fana ka ts'epo:

- Mechini e Boima: Lithupa tsa cylinder cylinder le likarolo tsa crane moo matla a eona a chai e phahameng a hananang le ho kobeha ka tlas'a meroalo e boima, 'me khanyetso ea eona ea kutu e mamella maemo a kantle kapa a indasteri.

- Lisebelisoa tse nepahetseng: Li-spindle tsa lisebelisoa tsa mochini le matsoho a robotiki moo botsitso ba eona bo boholo (coefficient e tlase ea katoloso ea mocheso: 23.6 μm/(m·K)) e netefatsa ts'ebetso e tsitsitseng esita le nakong ea nako e telele ea tlhahiso.

Marine & Offshore

Le ha aluminium e se khetho ea pele bakeng sa lits'ebetso tsa metsing, 7075 T652 (e nang le kalafo e nepahetseng ea holim'a metsi) e ipabola ho:

- Marine Hardware: Li-shafts tsa propeller ea likepe le lisebelisoa tsa lisebelisoa moo moralo oa eona o bobebe o nolofatsang ho kengoa, 'me khanyetso ea eona ea kutu (ha e tlotsoa) e mamella ho pepeseha ha metsi a letsoai.

Selekane le Rona Bakeng sa Li-Premium 7075 T652 Forged Aluminium Bars

Re ikhethela ho hlahisa7075 T652 e entsoeng ka aluminium mekoallotse kopanang le maemo a thata a indasteri ho tloha ho ASTM ho isa ho AMS. Mokhoa oa rona oa ho qhekella o sebelisa lisebelisoa tsa morao-rao ho netefatsa sebopeho se ts'oanang sa lijo-thollo, 'me sehlopha se seng le se seng se etsa liteko tse matla (teko ea ho tiea, tlhahlobo ea boima ba 'mele le tlhahlobo ea sebopeho sa lik'hemik'hale) ho netefatsa ts'ebetso e tsitsitseng. Hore na o hloka bolelele ba tloaelo, li-diameter, kapa kalafo ea bokaholimo (anodizing, coating ea phofo), sehlopha sa rona sa boenjiniere se sebetsa le uena ho fana ka litharollo tse lumellanang le kopo ea hau.

Bakeng sa baetsi ba lifofane, likoloi, kapa indasteri ba batlang tharollo ea aluminium e matla, e bobebe, 7075 T652 e entsoeng ka aluminium bars ke karabo. Ikopanye le rona kajeno ho kopa database ea tekheniki

Nako ea poso: Nov-17-2025