Sida hormuudka bixiya agabka aluminiumka iyoadeegyada machining CNC saxda ah, Shanghai Miandi Metal Products Co., Ltd. waxay ku takhasustay bixinta aluminium aluminium tayo sare leh oo loogu talagalay wax-shiidka, leexinta, iyo farsamaynta CNC. Haddii aad u baahan tahay qaybo khafiif ah oo leh joomatari qallafsan ama qaybo aad u sarreeya oo loogu talagalay warshadaha dalbanaya, khibraddayada xulashada alwaaxyada iyo farsamaynta waxay hubisaa saxnaanta iyo isku halaynta aan la isku halayn karin.

1. Aluminiumka Furaha ee Aluminiumka ah ee Mashiinka CNC

Mashiinka CNC wuxuu u baahan yahay alloys oo dheellitiraya mashiinnada, xasilloonida cabbirka, dhammaystirka dusha sare, iyo sifooyinka farsamada. Hoos waxaa ku yaal taxanaha aluminium ee loogu isticmaalka badan yahay iyo faa'iidooyinkooda gaarka ah:

a. 6000 Taxane Aluminium (6061, 6063)

Halabuurka Muhiimka ah: Silikoon (Si) iyo magnesium (Mg) oo ah curiyeyaasha alloying aasaasiga ah (tusaale, 6061: 0.6% Si, 1.0% Mg).

Machinability: Samaynta chip heer sare ah iyo xoogag goynta hooseeya, oo ku habboon hawlaha CNC-xawaaraha sare leh. Dhammaystir dusha sare leh (Ra ≤ 1.6μm) oo la gaari karo iyada oo aan dib-u-habeyn ballaaran.

Qalabka Farsamada: Xoog dhexdhexaad ah (UTS: 260-310 MPa ee T6 xanaaqa), caabbinta daxalka wanaagsan, iyo weldability. Heat-la daweyn karo (T4 / T6 tempering) ee la xoojiyey qallafsanaanta iyo sharafta qaabdhismeedka.

Codsiyada caadiga ah: Qalabka hawada sare, qaybaha baabuurta, qaybo ka mid ah robotics, iyo alluminium extrusions.

Maxaad noo doorataa: Waxaan bixinaa 6061-T6 / T651 aluminium taarikada / ulo leh oo leh dulqaad cabbir adag (± 0.01 mm), diyaar u ah wax-shiidka CNC-ga sare ee saxda ah.

b. 7000 Taxane Aluminium (7075)

Halabuurka Muhiimka ah: Zinc (Zn) oo ah xoojinta aasaasiga ah, oo leh Mg iyo Cu (tusaale, 7075: 5.6% Zn, 2.5% Mg).

Machinability: Adag ka sarreeya taxanaha 6000 wuxuu u baahan yahay qalab carbide ama PCD, laakiin wuxuu bixiyaa saxnaanta goynta sare ee qaababka adag

Qalabka Farsamada: Awood aad u sarreeya (UTS: ilaa 572 MPa ee xanaaqa T651), taas oo ka dhigaysa mid ka xoog badan biro badan inta ay ku harsan tahay miisaanka.

Codsiyada caadiga ah: Qaybaha qaab dhismeedka diyaarada (tusaale, qaybaha garabka), chassis motorsport, iyo caaryada saxda ah.

Faa'iidadayada: Premium 7075-T651 ulaha aluminium/taaradaha leh buufin-dejinta walaaca, hoos u dhigista mashiinnada-ku-dagaalanka.

c. Aluminium Taxane 2000 (2024)

Halabuurka Muhiimka ah: Copper (Cu) oo ku salaysan Mg/Mn (tusaale, 2024: 4.4% Cu, 1.5% Mg).

Machinability:Mashiinka Wanaagsan (gaar ahaan gobolada la jeexjeexay) ee CNC rogid iyo shiidid, in kastoo xanaaqa adag (T8) u baahan qalab adag. Awood u leh in la gaaro dulqaad adag qaybaha hawada hawada.

Guryaha Makaanikada: Xoog sare (UTS: 470-485 MPa ee T351 xanaaq) iyo iska caabin daal aad u fiican. Kulayl-ku-daweyn loogu talagalay qallafsanaanta ee codsiyada xajinta.

Codsiga caadiga ah: Spars baalasha diyaaradda, qaybaha geerarka, iyo qaybaha farsamada ee waxqabadka sareeyo.

d. 5000 Taxane Aluminium (5052, 5083)

Halabuurka Muhiimka ah: Magnesium (Mg) - taajir ah (tusaale, 5052: 2.5% Mg).

Machinability: Jilicsan iyo ductile, ku habboonCNC samaynta iyo foorarid la'aandildilaaca

Guryaha Makaanikada: Xoog dhexdhexaad ah oo leh iska caabin daxaleed gaar ah (ku habboon bey'adaha badda ama bannaanka).Aan kuleyl lagu daweyn karin, laakiin adkeynta shaqadu waxay kordhisaa cimriga.

Codsiga caadiga ah: Goosha doonyaha, qalabka kiimikaad, iyo qaybaha qurxinta ee CNC-mashiinka

Bixintayada: 2024-T351 taarikada aluminiumka ah oo shahaado u leh heerarka hawada hawada (tusaale, AMS 4042).

2. Faa'iidooyinka Mashiinka CNC ee Aluminium Alloys

a. Guryaha Alaabta Lagu Wanaajiyey Sax ahaan

Cufnaanta Hoose: 2.7 g/cm³ (1/3 culeyska birta), hoos u dhigida firfircoonida farsamaynta degdegga ah iyo alaabta dhamaadka fudud.

Dhaqdhaqaaqa Kulaylka: Kala-baxa kulaylka sare wuxuu yareeyaa xirashada qalabka iyo qallafsanaanta kulaylka inta lagu jiro goynta xawaaraha sare.

Dabeecadda Isotropic: Qalabka farsamada ee isku midka ah ee dhammaan jihooyinka, hubinta natiijooyinka mashiinnada joogtada ah.

b. Waxtarka Mashiinka & Waxtarka Kharashka

Xawaaraha Goynta Sare: Aluminiumku wuxuu u oggolaanayaa heerarka quudinta ilaa 5000 mm / min (waxay kuxirantahay alloy), yaraynta waqtiyada wareegga.

Waafaqsanaanta Qalabka: La jaanqaadi kara kaarbiide, HSS, iyo agabka PCD, oo bixiya dabacsanaan xagga qallafsanaanta iyo dhamaystirka hawlgallada.

Xakamaynta Chip: Alloys-ka Ductile sida 6061 waxay soo saaraan jajabyo joogto ah, halka darajooyinka mishiinka bilaashka ah (tusaale, 6061 oo lagu daray Pb/Bi) ay dhaliyaan jajabyo jajaban oo loogu talagalay farsamaynta otomaatiga ah.

c. Dabacsanaanta ka-hortagista

Dhamaystirka dusha sare: Anodizing, daahan budada ah, korantada samaynta, ama qarxinta kuul si kor loogu qaado bilicda iyo caabbinta daxalka.

Daawaynta Kulaylka: Dabciga gaarka ah (tusaale, T6) si loo gaaro adkaanta bartilmaameedka iyo dhimista walaaca ka dib mashiinka.

3. Shanghai Miandi's CNC Machining Solutions for Aluminum

Ka faa'iidayso awoodeena dhamaadka-ilaa-dhamaadka si aan ugu beddelno aluminium alloys qaybo sax ah:

a. Alaabta

Taxane buuxa oo aluminium aluminium ah: 6061, 7075, 2024, 5052 ee taarikada, ulo, tuubooyinka, iyo extrusions caadada, oo laga keenay warshado shahaadaysan.

Xulashada Xanaaqa: Annealed (O), xal-la daweeyay (T4), da'da (T6), iyo stress-defid (T651) si ay u buuxiyaan shuruudaha machining iyo waxqabadka.

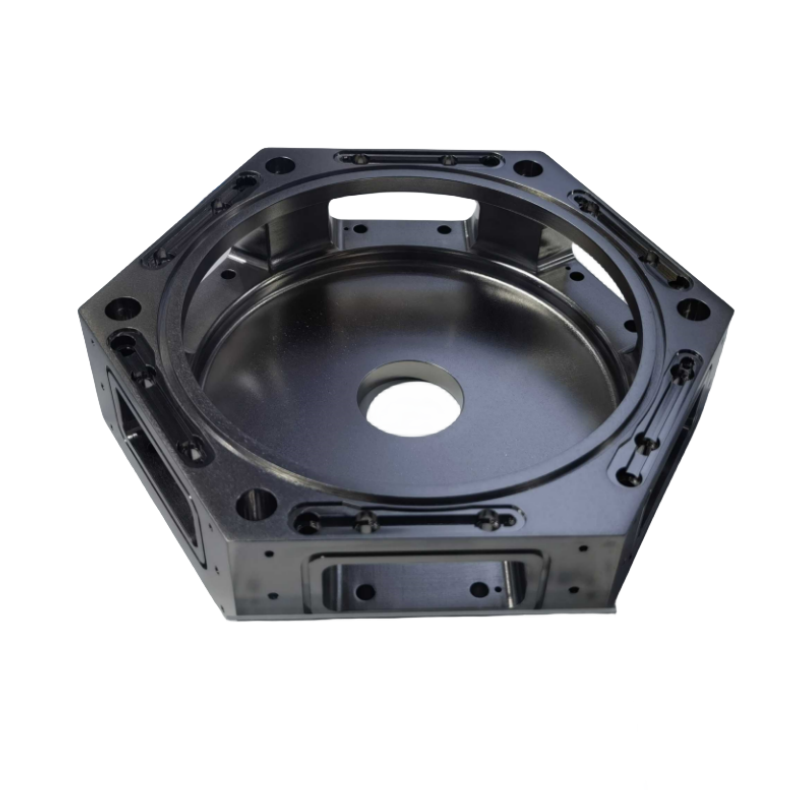

b. Adeegyada CNC ee saxda ah

Awoodaha Mashiinka:

3/4/5-dhidibka CNC-shiidida ee joomatariyada adag (tusaale, hawo hawada sare, qalabka caafimaadka).

CNC waxay u rogtay ulaha, hub-yada, iyo qaybaha cylindrical (dulqaad: ± 0.005 mm).

Mashiinka Swiss ee qaybaha saxda ah ee saxda ah (dhexroor: 0.5-20 mm).

Habka kaalmaynta: qodista, taabsiinta, dunta, faaqidaadda, iyo EDM ee sifooyin adag.

c. Xaqiijinta Tayada

TS EN ISO 9001: 2015 shahaado: Kormeer adag oo ku saabsan kiimikada walxaha, sifooyinka farsamada, iyo saxnaanta cabbirka (CMM / cabbirka indhaha).

Taageerada DFM: La-talinta naqshadaynta-mashiinka-qaabaynta bilaashka ah si kor loogu qaado qayb joomatari kharashka iyo hufnaanta.

d. Is-habaynta & Miisaanka

Muunad dufcad yar oo wax-soo-saarka mugga sare leh, oo leh isbeddel degdeg ah (7-10 maalmood ee tusaalooyinka).

U hoggaansanaanta warshadaha: Alaabta shahaado u leh ASTM, AMS, GB, ama heerarka ISO, oo wata dukumeenti la raadraaco hawada hawada iyo macaamiisha baabuurta.

4. Maxaad u doorataa Aluminium Machining CNC?

Miisaanka-Xoogga Miisaanka: Ku habboon codsiyada halka naqshadeynta fudud ay muhiim tahay (tusaale, hawada sare, diyaaradaha aan duuliyaha lahayn).

Kharash wax ku ool ah: Waxyaalaha iyo mashiinada ka hooseeya titanium ama birta, oo leh dib u warshadayn heer sare ah.

Xoriyadda Naqshadeynta: Qaabab isku dhafan, darbiyo dhuuban, iyo dulqaad adag oo lagu gaari karo qalabka CNC ee casriga ah.

La xidhiidh Shanghai Miandi Maanta wixii loogu talagalayXalalka mashiinka CNC iyadoo la isticmaalayo aluminium aluminium premium ah. Haddii aad u baahan tahay hal nooc ama qaybo badan oo la soo saaray, khibradeena xagga xulashada daawaha, saxnaanta farsamaynta, iyo xakamaynta tayada waxay hubisaa in mashruucaagu guulaysto.

Shanghai Miandi Metal Products Co., Ltd. - Saxnaanta gooyo kasta.

Waqtiga boostada: Jun-12-2025