Monga wotsogola wotsogola wa zida za aluminiyamu zapamwamba komansomwatsatanetsatane CNC Machining misonkhano. Kaya mumafunikira zida zopepuka zokhala ndi ma geometri odabwitsa kapena zida zamphamvu kwambiri zamafakitale ofunikira, ukadaulo wathu pakusankha aloyi ndi makina amatsimikizira kulondola kosayerekezeka ndi kudalirika.

1. Key Aluminiyamu Aloyi kwa CNC Machining

Makina a CNC amafunikira ma alloys omwe amalinganiza machinability, kukhazikika kwa mawonekedwe, kutha kwa pamwamba, ndi zida zamakina. M'munsimu muli mndandanda wa aluminiyamu womwe umagwiritsidwa ntchito kwambiri komanso ubwino wawo wapadera:

a. 6000 Series Aluminium (6061, 6063)

Mapangidwe a Core: Silicon (Si) ndi magnesium (Mg) monga zinthu zoyambira zowonjezera (mwachitsanzo, 6061: 0.6% Si, 1.0% Mg).

Kuthekera: Kupanga bwino kwa chip ndi mphamvu zochepa zodulira, zabwino kwambiri zogwirira ntchito za CNC zothamanga kwambiri.Smooth surface finish (Ra ≤ 1.6μm) zomwe zingapezeke popanda kukonzanso kwakukulu pambuyo pokonza.

Katundu Wamakina: Mphamvu zapakatikati (UTS: 260–310 MPa mu kupsa mtima kwa T6), kukana bwino kwa dzimbiri, komanso kutenthedwa. Kutentha kwapang'onopang'ono (T4/T6 tempering) kulimbitsa kulimba komanso kukhulupirika kwamapangidwe.

Ntchito zofananira: Mabulaketi apamlengalenga, zida zamagalimoto, zida zama robotic, ndi zotulutsa aluminiyamu.

Chifukwa Chomwe Tisankhire: Timapereka ma 6061-T6/T651 aluminium mbale/ndodo zokhala ndi zolimba zowoneka bwino (± 0.01 mm), zokonzekera mphero yolondola kwambiri ya CNC.

b. 7000 Series Aluminium (7075)

Mapangidwe a Core: Zinc (Zn) monga cholimbikitsa choyamba, ndi Mg ndi Cu (mwachitsanzo, 7075: 5.6% Zn, 2.5% Mg).

Machinability: Kuuma kwakukulu kuposa mndandanda wa 6000 kumafuna zida za carbide kapena PCD, koma zimapereka kudulidwa kwapamwamba kwa mawonekedwe ovuta.

Zida zamakina: Mphamvu yapamwamba kwambiri (UTS: mpaka 572 MPa mu T651 temper), imapangitsa kuti ikhale yolimba kuposa zitsulo zambiri pamene imakhala yopepuka.

Zomwe zimagwiritsidwa ntchito: Zigawo za ndege (monga zigawo zamapiko), chassis ya motorsport, ndi nkhungu zolondola.

Ubwino Wathu: Ndodo/mbale za aluminiyamu za Premium 7075-T651 zokhala ndi ma annealing ochepetsa kupsinjika, kuchepetsa tsamba lankhondo lopangidwa ndi makina.

c. 2000 Series Aluminium (2024)

Mapangidwe Apakati: Mkuwa (Cu)-yochokera ndi Mg/Mn (mwachitsanzo, 2024: 4.4% Cu, 1.5% Mg).

Kuthekera:Kuchita bwino (makamaka m'maiko osasinthika) kwa CNC kutembenuka ndi mphero, ngakhale kupsya mtima kolimba (T8) kumafuna zida zolimba.Kutha kukwaniritsa kupirira kolimba kwa zigawo zamagawo amlengalenga.

Katundu Wamakina: Mphamvu yayikulu (UTS: 470–485 MPa mu kupsya mtima kwa T351) komanso kukana kutopa kwambiri. Kutentha kumatha kupirira kuuma kokwanira pakunyamula katundu.

Ntchito yodziwika bwino: Mapiko a ndege, zida zoikira, ndi zida zamakina ochita bwino kwambiri.

d. 5000 Series Aluminium (5052, 5083)

Mapangidwe a Core: Magnesium (Mg) -olemera (mwachitsanzo, 5052: 2.5% Mg).

Kuthekera: Yofewa komanso yodumphira, yabwino kwaCNC kupanga ndi kupinda popandacracking.Mapeto abwino kwambiri azinthu zokongoletsa kapena zowononga dzimbiri.

Katundu Wamakina:Kulimba kocheperako kosagwirizana ndi dzimbiri (zabwino m'madzi kapena kunja). Zosatha kutentha, koma kuwumitsa ntchito kumawonjezera kulimba.

Kugwiritsiridwa ntchito kofananira: Zipinda za ngalawa, zida zamakina, ndi zida zodzikongoletsera zopangidwa ndi makina a CNC.

Kupereka Kwathu: 2024-T351 mbale za aluminiyamu zovomerezeka pazamlengalenga (mwachitsanzo, AMS 4042).

2. CNC Machining Ubwino wa Aluminiyamu Aloyi

a. Zakuthupi Zokometsedwa Kuti Zikhale Zolondola

Kachulukidwe Wochepa: 2.7 g/cm³ (1/3 kulemera kwa chitsulo), kuchepetsa mphamvu ya makina othamanga komanso zinthu zopepuka.

Thermal Conductivity: Kutentha kwakukulu kumachepetsa kuvala kwa zida ndi kusinthika kwamafuta panthawi yodula kwambiri.

Makhalidwe a Isotropic: Mawonekedwe amakina ofananira mbali zonse, kuwonetsetsa kuti makina azitsatira.

b. Kuchita bwino kwa Machining & Kugwiritsa Ntchito Ndalama

Kuthamanga Kwambiri Kwambiri: Aluminiyamu imalola kuti chakudya chifike ku 5000 mm / min (malingana ndi aloyi), kuchepetsa nthawi yozungulira.

Kugwirizana kwa Chida: Kugwirizana ndi zida za carbide, HSS, ndi PCD, zomwe zimapereka kusinthasintha kwakuchita roughing ndi kumaliza.

Chip Control: Ma ductile alloys ngati 6061 amatulutsa tchipisi chopitilira, pomwe magiredi opangira ma free-machining (mwachitsanzo, 6061 okhala ndi Pb/Bi) amatulutsa tchipisi tosweka kuti tipange makina.

c. Post-Processing Flexibility

Kumaliza Pamwamba: Kupaka mafuta, kupaka ufa, electroplating, kapena kuphulika kwa mikanda kuti apititse patsogolo kukongola ndi kukana dzimbiri.

Kuchiza Kutentha: Kutentha kwachizolowezi (mwachitsanzo, T6) kuti mukwaniritse kuuma kwa chandamale ndi kupsinjika maganizo mutatha kukonza.

3. Shanghai Miandi's CNC Machining Solutions for Aluminium

Gwiritsani ntchito mphamvu zathu zakumapeto-kumapeto kuti tisinthe ma aloyi a aluminiyamu kukhala zigawo zolondola:

a. Kupereka Zinthu Zofunika

Mitundu yonse ya aluminiyamu aloyi: 6061, 7075, 2024, 5052 m'mbale, ndodo, machubu, ndi ma extrusions omwe amapangidwa kuchokera ku mphero zovomerezeka.

Zosankha za Kutentha: Annealed (O), solution-treated (T4), okalamba (T6), ndi kuchepetsa nkhawa (T651) kuti akwaniritse zofunikira za makina ndi ntchito.

b. Precision CNC Services

Kuthekera kwa Makina:

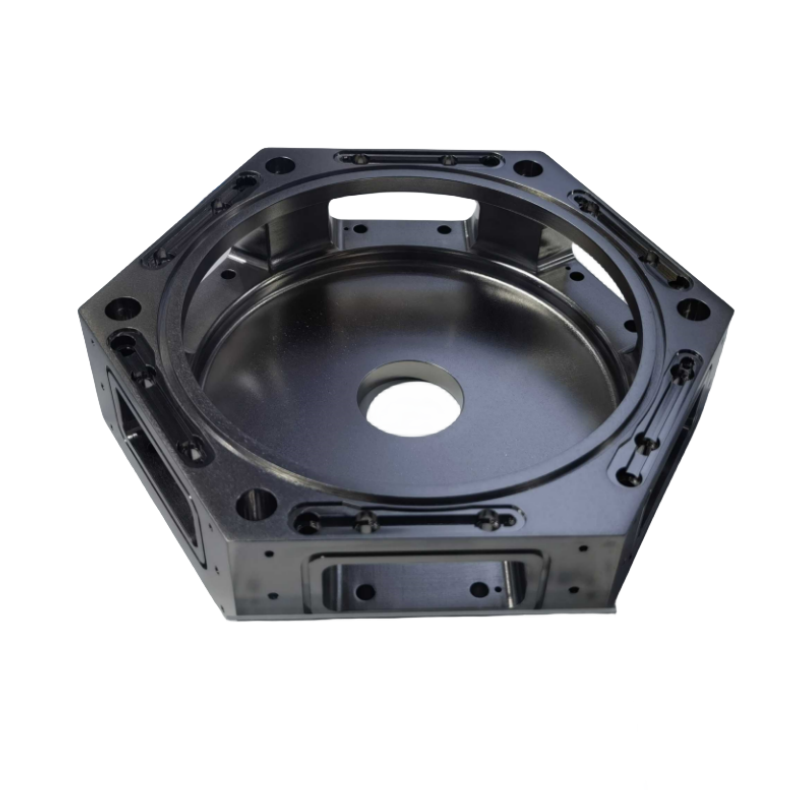

3/4/5-axis CNC mphero ya ma geometries ovuta (monga mabulaketi apamlengalenga, zida zamankhwala).

CNC kutembenukira kwa shafts, hubs, ndi cylindrical mbali (kulolerana: ± 0.005 mm).

Makina aku Swiss azinthu zolondola kwambiri (m'mimba mwake: 0.5-20 mm).

Njira yothandizira: Kubowola, kugogoda, kulumikiza, kulumikiza, ndi EDM pazinthu zovuta.

c. Chitsimikizo chadongosolo

ISO 9001: 2015 Yotsimikizika: Kuyang'ana mozama kwa chemistry yazinthu, makina amakina, ndi kulondola kwazithunzi (CMM/kuyeza kwa kuwala).

Thandizo la DFM: Kufunsira kwaulere pamakina kuti mukwaniritse gawo la geometry pamtengo wake komanso kuchita bwino.

d. Kusintha Mwamakonda & Scalability

Zitsanzo zazing'ono zamagulu ang'onoang'ono kuti apange kuchuluka kwakukulu, ndikusintha mwachangu (masiku 7-10 a prototypes).

Kutsata kwamakampani: Zida zovomerezeka ku ASTM, AMS, GB, kapena ISO miyezo, zokhala ndi zolemba zotsatirika zamakasitomala apamlengalenga ndi magalimoto.

4. Chifukwa Sankhani Aluminiyamu kwa CNC Machining?

Kulemera kwamphamvu: Ndikoyenera kugwiritsa ntchito pomwe mapangidwe opepuka amakhala ovuta (mwachitsanzo, zakuthambo, ma drones).

Zotsika mtengo: Zotsika mtengo komanso zopangira makina kuposa titaniyamu kapena chitsulo, zomwe zimatha kubwezeretsedwanso bwino.

Ufulu Wopanga: Mawonekedwe ovuta, makoma owonda, komanso kulolerana kolimba komwe kumatheka ndi zida zamakono za CNC.

Lumikizanani ndi Shanghai Miandi Today kuti mugwirizaneCNC Machining mayankho ntchito umafunika zotayidwa zotayidwa. Kaya mukufuna fanizo limodzi kapena zida zopangidwa mochuluka, ukadaulo wathu pakusankha aloyi, kulondola kwa makina, ndi kuwongolera bwino kumatsimikizira kuti polojekiti yanu ikuyenda bwino.

Shanghai Miandi Metal Products Co., Ltd. - Precision in Every Cut.

Nthawi yotumiza: Jun-12-2025