Raws li tus neeg muab kev pabcuam zoo tshaj plaws aluminium cov ntaub ntawv thiabprecision CNC machining cov kev pab cuamShanghai Miandi Hlau Khoom Co., Ltd. specializes nyob rau hauv xa high-kev ua tau zoo txhuas alloys optimized rau CNC milling, tig, thiab fabrication. Txawm hais tias koj xav tau cov khoom sib sib zog nqus nrog cov geometry tsis sib xws los yog qhov chaw muaj zog rau kev xav tau kev lag luam, peb cov kws tshaj lij hauv kev xaiv alloy thiab machining kom tsis txhob muaj qhov sib txawv thiab kev ntseeg tau.

1. Ntsiab Aluminium Alloys rau CNC Machining

CNC machining yuav tsum tau alloys uas sib npaug machinability, seem stability, nto tiav, thiab txhua yam khoom. Hauv qab no yog cov feem ntau siv aluminium series thiab lawv qhov tshwj xeeb zoo:

a. 6000 Series Aluminium (6061, 6063)

Cov ntsiab lus tseem ceeb: Silicon (Si) thiab magnesium (Mg) ua cov ntsiab lus alloying (piv txwv li, 6061: 0.6% Si, 1.0% Mg).

Machinability: Kev tsim cov nti zoo heev thiab tsis tshua muaj zog txiav, zoo tagnrho rau kev ua haujlwm siab CNC.Smooth nto tiav (Ra ≤ 1.6μm) tuaj yeem ua tiav yam tsis muaj kev ua tiav tom qab.

Mechanical Properties: Lub zog nruab nrab (UTS: 260-310 MPa hauv T6 temper), zoo corrosion kuj, thiab weldability.Heat-treatable (T4 / T6 tempering) rau kev txhim kho hardness thiab structural kev ncaj ncees.

Cov ntawv thov: Aerospace brackets, automotive Cheebtsam, robotics qhov chaw, thiab txhuas extrusion.

Vim Li Cas Xaiv Peb: Peb muab 6061-T6 / T651 txhuas daim hlau / pas nrig nrog nruj qhov ntev kam rau ua (± 0.01 hli), npaj rau high-precision CNC milling.

b. 7000 Series Txhuas (7075)

Cov ntsiab lus tseem ceeb: Zinc (Zn) ua lub zog tseem ceeb, nrog Mg thiab Cu (piv txwv li, 7075: 5.6% Zn, 2.5% Mg).

Machinability: Siab hardness tshaj 6000 series yuav tsum tau carbide los yog PCD cov cuab yeej, tab sis muaj superior txiav precision rau complex duab.Excellent kuj rau deformation thaum lub sij hawm hnyav machining.

Mechanical Properties: Ultra-siab zog (UTS: mus txog 572 MPa nyob rau hauv T651 temper), ua rau nws muaj zog tshaj li ntau steels thaum tshuav lub teeb yuag.High qaug zog tsis kam, tseem ceeb rau aerospace thiab high-stress industrial applications.

Daim ntawv thov: Aircraft structural parts (xws li, tis yam), motorsport chassis, thiab precision pwm.

Peb Qhov Zoo: Hwm 7075-T651 txhuas rods / daim hlau nrog kev ntxhov siab-relieved annealing, minimizing machining-induced warpage.

c. 2000 Series Txhuas (2024)

Cov ntsiab lus tseem ceeb: tooj liab (Cu)-raws li Mg / Mn (piv txwv li, 2024: 4.4% Cu, 1.5% Mg).

Machinability: Zoo machinability (tshwj xeeb tshaj yog nyob rau hauv lub xeev annealed) rau CNC tig thiab milling, tab sis nyuaj tempers (T8) yuav tsum robust tooling. Muaj peev xwm ua tau kom nruj tolerances rau aerospace-qib Cheebtsam.

Mechanical Properties: Siab zog (UTS: 470-485 MPa nyob rau hauv T351 temper) thiab zoo heev qaug zog kuj.Heat-treatable rau optimized hardness nyob rau hauv load-bearing daim ntaub ntawv.

Daim ntawv thov ib txwm: Lub dav hlau tis spars, tsaws iav qhov chaw, thiab cov khoom siv tshuab ua haujlwm siab.

d. 5000 Series Txhuas (5052, 5083)

Cov ntsiab lus tseem ceeb: Magnesium (Mg)-nplua nuj (piv txwv li, 5052: 2.5% Mg).

Machinability: Mos thiab ductile, zoo tagnrho rauCNC sib sau thiab khoov tsis muajcracking.Excellent nto tiav rau cov hniav los yog corrosion-rhiab qhov chaw.

Mechanical Properties: Lub zog nruab nrab nrog kev tiv thaiv corrosion tshwj xeeb (zoo tagnrho rau cov chaw hauv dej hiav txwv lossis sab nraum zoov).Non-kub-kho, tab sis ua hauj lwm-hardening txhim khu durability.

Daim ntawv thov: Lub nkoj hulls, cov khoom siv tshuaj, thiab CNC-machined decorative Cheebtsam.

Peb Muab: 2024-T351 txhuas daim hlau ntawv pov thawj rau aerospace cov qauv (xws li, AMS 4042).

2. CNC Machining Qhov Zoo ntawm Aluminium Alloys

a. Material Properties Optimized rau Precision

Tsawg Ceev: 2.7 g / cm³ (1/3 lub luj ntawm cov hlau), txo inertia kom ceev machining thiab sib zog kawg khoom.

Thermal Conductivity: High tshav kub dissipation txo cov cuab yeej hnav thiab thermal deformation thaum lub sij hawm high-ceev txiav.

Isotropic Behavior: Uniform mechanical zog nyob rau hauv tag nrho cov lus qhia, kom ntseeg tau tias zoo ib yam machining tau.

b. Machining Efficiency & Nqi-Effectiveness

High Cutting Speeds: Aluminium tso cai pub tus nqi nce txog 5000 mm / min (nyob ntawm cov alloy), txo lub sijhawm voj voog.

Tool Compatibility: Tau tshaj carbide, HSS, thiab PCD cov cuab yeej, muab kev yooj yim rau roughing thiab ua tiav cov haujlwm.

Chip Control: Ductile alloys zoo li 6061 tsim cov chips txuas ntxiv, thaum cov qib ua haujlwm pub dawb (piv txwv li, 6061 nrog ntxiv Pb / Bi) tsim cov chips tawg tau rau kev siv tshuab.

c. Tom qab ua Flexibility

Deg Finishing: Anodizing, hmoov txheej, electroplating, los yog hlaws blasting los txhim kho kev zoo nkauj thiab corrosion kuj.

Kev kho cua sov: Kev cai tempering (xws li, T6) kom ua tiav lub hom phiaj hardness thiab kev ntxhov siab tom qab machining.

3. Shanghai Miandi's CNC Machining Solutions rau Aluminium

Leverage peb qhov kawg-rau-kawg muaj peev xwm hloov pauv aluminium alloys rau hauv cov khoom precision:

a. Khoom siv

Tag nrho series ntawm txhuas alloy: 6061, 7075, 2024, 5052 nyob rau hauv daim hlau, rods, hlab, thiab kev cai extrusion, los ntawm cov ntawv pov thawj mills.

Temper Options: Annealed (O), kev daws teeb meem (T4), hnub nyoog (T6), thiab kev ntxhov siab (T651) kom ua tau raws li kev ua haujlwm thiab kev ua haujlwm.

b. Precision CNC Services

Machining peev xwm:

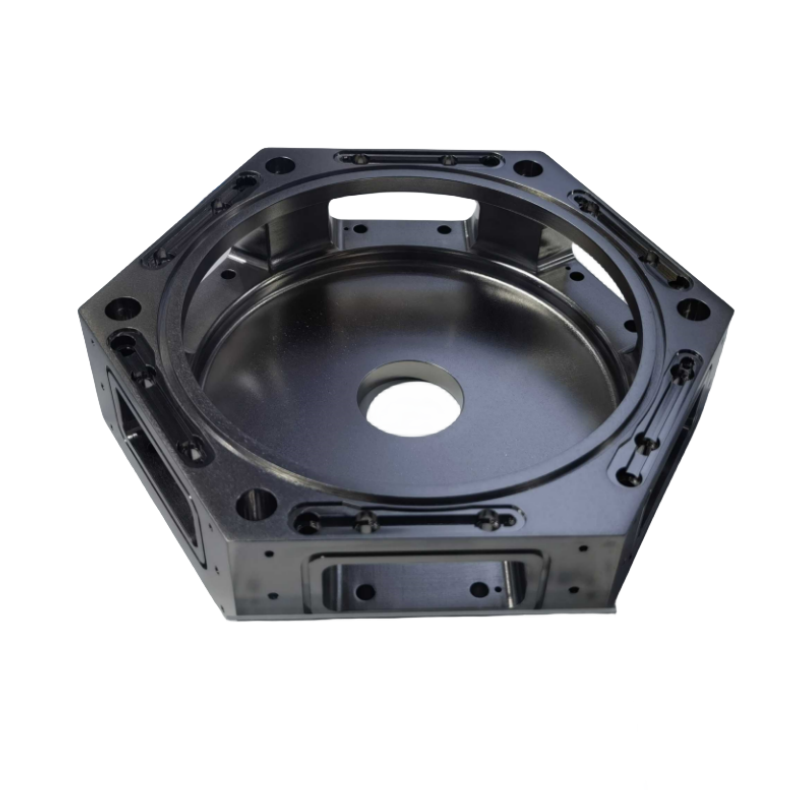

3/4/5-axis CNC milling rau complex geometries (xws li, aerospace brackets, kho mob).

CNC tig rau shafts, hubs, thiab cylindrical qhov chaw ( kam rau ua: ± 0.005 hli).

Swiss machining rau micro-precision Cheebtsam (inch: 0.5-20 mm).

Cov txheej txheem pabcuam: Drilling, tapping, threading, broaching, thiab EDM rau cov yam ntxwv zoo sib xws.

c. Quality Assurance

ISO 9001: 2015 Certified: Kev soj ntsuam nruj ntawm cov khoom siv chemistry, cov khoom siv kho tshuab, thiab qhov tseeb qhov tseeb (CMM / optical ntsuas).

DFM Kev them nyiaj yug: Dawb tsim-rau-machining kev sab laj kom optimize ib feem geometry rau nqi thiab efficiency.

d. Customization & Scalability

Me me batch sampling rau high-volume ntau lawm, nrog ceev ceev turnaround (7-10 hnub rau prototypes).

Kev ua raws li kev lag luam: Cov ntaub ntawv pov thawj rau ASTM, AMS, GB, lossis ISO cov qauv, nrog cov ntaub ntawv pov thawj rau aerospace thiab cov neeg siv tsheb.

4. Vim li cas thiaj xaiv Aluminium rau CNC Machining?

Qhov hnyav-Strength Balance: Zoo tagnrho rau cov ntawv thov uas tsim qauv hnyav yog qhov tseem ceeb (piv txwv li, aerospace, drones).

Tus nqi-zoo: Cov khoom siv qis dua thiab cov nqi machining dua li titanium lossis hlau, nrog rau kev rov ua dua tshiab.

Tsim Kev ywj pheej: Cov duab tsis yooj yim, cov phab ntsa nyias, thiab kev ua siab ntev ntev tuaj yeem ua tiav nrog cov cuab yeej CNC niaj hnub.

Hu rau Shanghai Miandi Hnub no kom haumCNC machining kev daws teeb meem siv hwm aluminium alloys. Txawm hais tias koj xav tau ib qho qauv lossis cov khoom tsim tawm ntau, peb cov kws tshaj lij hauv kev xaiv alloy, machining precision, thiab kev tswj kom zoo ua kom koj qhov project ua tiav.

Shanghai Miandi Hlau Khoom Co., Ltd. - Precision nyob rau hauv txhua txiav.

Post lub sij hawm: Jun-12-2025