I ka wā o ka hoʻokele waiwai, ʻike pinepine ʻia nā huahana nani e nā poʻe he nui, a loaʻa ka mea i kapa ʻia ma o ka ʻike a me ka hoʻopā ʻana. No kēia manaʻo, he mea koʻikoʻi ka mālama ʻana i ka ʻili. No ka laʻana, hana ʻia ka pūpū o ka lolouila me kahi ʻāpana alumini holoʻokoʻa ma o ka hana ʻana o CNC o ke ʻano, a laila hoʻoliʻiliʻi ʻia, wili kiʻekiʻe kiʻekiʻe a me nā kaʻina hana ʻē aʻe e hana like ai kona ʻano metala me ke ʻano a me ka ʻenehana. He mea maʻalahi ka hana ʻana i ka alumini alumini, loaʻa nā ʻano hana lapaʻau waiwai, a me nā hopena ʻike maikaʻi. Hoʻohana nui ʻia ia i nā laptops, kelepona paʻalima, nā kamera a me nā huahana ʻē aʻe. Hoʻohui pinepine ʻia me nā kaʻina hana lapaʻau e like me ka polishing, brushing, sandblasting, high-gloss cutting and anodizing e hana i ka huahana e hōʻike i nā ʻano like ʻole.

Pōlani

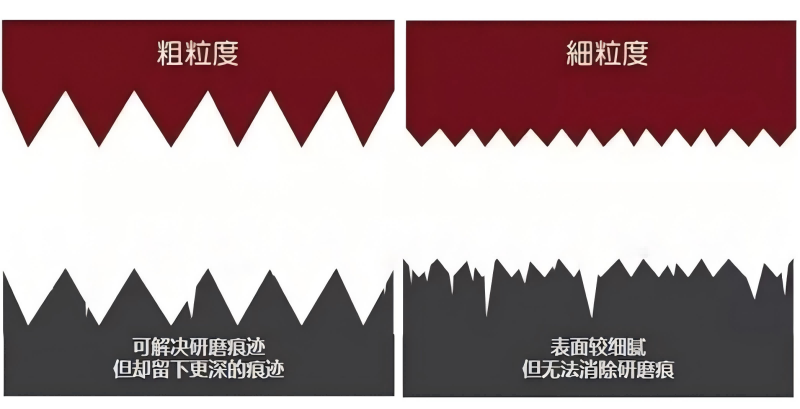

ʻO ke kaʻina hana polishing ka mea e hōʻemi nui ai i ka roughness o ka ʻili metala ma o ka polishing mechanical a i ʻole ka polishing chemical, akā ʻaʻole hiki i ka polishing ke hoʻomaikaʻi i ka pololei dimensional a i ʻole ka pololei geometric shape o nā ʻāpana, akā hoʻohana ʻia e kiʻi i kahi ʻano maʻemaʻe a i ʻole ke aniani.

Hoʻohana ʻia ka ʻili ʻana me ka mīkini i ka pepa ʻeleʻele a i ʻole nā huila polishing e hōʻemi ai i ka ʻawaʻawa a hana i ka ʻili metala palahalaha a ʻālohilohi. Eia naʻe, ʻaʻole kiʻekiʻe ka paʻakikī o ka alumini alumini, a me ka hoʻohana ʻana i ka wili a me nā mea polishing e waiho i nā laina wili hohonu. Inā hoʻohana ʻia nā kīʻaha maikaʻi, ʻoi aku ka maikaʻi o ka ʻili, akā ua hoʻemi nui ʻia ka hiki ke wehe i nā laina wili.

ʻO ka polishing kemika he kaʻina hana electrochemical i hiki ke noʻonoʻo ʻia e like me ka reverse electroplating. Wehe ia i kahi ʻāpana lahilahi o nā mea ma luna o ka ʻili metala, e waiho ana i kahi ʻili maʻemaʻe a maʻemaʻe hoʻi me ka ʻōlinolino like ʻole a ʻaʻohe laina maikaʻi e ʻike ʻia i ka wā o ka poli kino.

Ma ke kahua lapaʻau, hiki i ka polishing kemika ke maʻalahi i ka hoʻomaʻemaʻe a me ka disinfect. I nā mea uila e like me nā pahu hau a me nā mīkini holoi, hiki i ka hoʻohana ʻana i nā huahana polishing kemika hiki ke hoʻolōʻihi i nā ʻāpana a loaʻa ke ʻano o ka nani. ʻO ka hoʻohana ʻana i ka polishing kemika i nā ʻāpana mokulele koʻikoʻi hiki ke hōʻemi i ke kūpaʻa friction, ʻoi aku ka maikaʻi o ka ikehu a me ka palekana.

Sandblasting

Nui nā huahana uila e hoʻohana i ka ʻenehana sandblasting e hana i ka ʻili o ka huahana i ʻoi aku ka maʻalahi matte paʻi, e like me ke aniani hau. He paʻa a paʻa ka mea matte, e hana ana i nā hiʻohiʻona haʻahaʻa a paʻa o ka huahana.

Hoʻohana ʻo Sandblasting i ka ea paʻa e like me ka mana e pīpī i nā mea, e like me ke one keleawe keleawe, ke one quartz, corundum, ke one hao, ke one kai, a me nā mea ʻē aʻe. nā ʻāpana alloy, e hoʻomaikaʻi i ke kūpaʻa luhi o nā ʻāpana, a me ka hoʻonui ʻana i ka adhesion ma waena o ka ʻili mua o nā ʻāpana a me nā uhi, ʻoi aku ka maikaʻi o ka lōʻihi o ka uhi ʻana a me ka pae ʻana a me ka hoʻonaninani o ka. ka uhi ʻana.

ʻO ke kaʻina hana hoʻomaʻemaʻe maʻemaʻe ʻoi aku ka wikiwiki a me ka hoʻomaʻemaʻe. Hiki iā ʻoe ke koho ma waena o nā ʻano ʻano like ʻole e hana i nā ʻano like ʻole ma ka ʻili o nā ʻāpana alumini.

Palaki

He mea maʻamau ka palaki ʻana i ka hoʻolālā huahana, e like me nā puke puke a me nā headphone i nā huahana uila, nā pahu hau a me nā mea hoʻomaʻemaʻe ea i nā huahana o ka hale, a hoʻohana ʻia hoʻi i loko o nā kaʻa. Hiki ke hoʻonui i ka maikaʻi o ke kaʻa i ka console kikowaena me kahi panel brushing.

ʻO ka ʻoki pinepine ʻana i nā laina ma luna o ka pā alumini me ka pepa ʻeleʻele hiki ke hōʻike maopopo i kēlā me kēia hōʻailona siliki maikaʻi, e hoʻomālamalama i ka metala matte me ka lauoho lauoho maikaʻi, e hāʻawi ana i ka huahana i ka nani a me ka lewa. E like me nā pono o ka hoʻonani, hiki ke hana ʻia i nā laina pololei, nā laina laina, nā laina spiral, etc.

ʻO ka umu microwave i lanakila i ka IF Award e hoʻohana i ka palaki ʻana ma luna o ka ʻili, nona ka nani paʻa a me ka lewa, e hui pū ana i ke ʻano a me ka ʻenehana.

Kiʻi ʻoniʻoni kiʻekiʻe

Ke hoʻohana nei ke kaʻina wili wili kiʻekiʻe i ka mīkini kalai pololei e ʻoki i nā ʻāpana a me ka hana ʻana i nā wahi kikoʻī kūloko ma ka ʻili o ka huahana. ʻO kekahi mau kelepona paʻa i kā lākou mau pūpū metala i wili ʻia me ka pōʻai o nā chamfers koʻikoʻi, a ʻo kekahi mau ʻāpana metala liʻiliʻi he hoʻokahi a i ʻole kekahi mau awāwa pololei pāpaʻu i wili ʻia e hoʻonui i nā hoʻololi ʻana o ka waihoʻoluʻu ʻālohilohi ma ka ʻili o ka huahana.

I kēia mau makahiki i hala iho nei, ua hoʻohana kekahi mau papa metala TV kiʻekiʻe i ke kaʻina hana wili wili kiʻekiʻe, a me nā kaʻina hana anodizing a me ka brushing e hoʻopiha ai i ka TV i ke ʻano a me ka ʻenehana.

Anodizing

I ka hapanui o nā hihia, ʻaʻole kūpono nā ʻāpana alumini no ka electroplating no ka mea maʻalahi loa nā ʻāpana alumini e hana i kahi kiʻiʻoniʻoni oxide ma ka oxygen, kahi e hoʻopilikia nui ai i ka ikaika paʻa o ka papa electroplating. Hoʻohana pinepine ʻia ka anodizing.

ʻO ka anodizing e pili ana i ka oxidation electrochemical o nā metala a i ʻole nā mea hao. Ma lalo o nā kūlana kūikawā a me ka hana o kahi manawa i hoʻopili ʻia, ua hoʻokumu ʻia kahi ʻāpana o ka alumini oxide film ma ka ʻili o ka ʻāpana, kahi e hoʻomaikaʻi ai i ka paʻakikī o ka ʻili a me ka pale ʻana o ka ʻili o ka ʻāpana a hoʻonui i ke kūpaʻa corrosion.

Eia kekahi, ma o ka mana adsorption o ka nui o nā micropores i loko o ke kiʻi ʻoniʻoni ʻoniʻoni ʻoniʻoni, hiki ke kala ʻia ka ʻili o ka ʻāpana i nā kala nani a nani, hoʻonui i ka hana kala o ka ʻāpana a hoʻonui i ka nani o ka huahana.

Ka manawa hoʻouna: Sep-05-2024