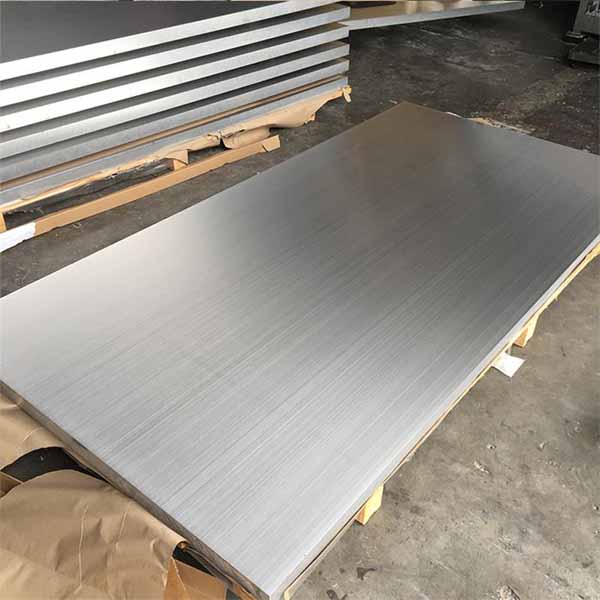

Isicelo solwakhiwo 782 I-Aluminium Plate 6082 t6

I-6082 Aluminium Alloy inamandla aphezulu kwazo zonke ii-alfays ezingama-6000.

Izicelo zesakhiwo

Idla ngokubizwa ngokuba 'yi-alloural' yesakhiwo ', i-6082 isetyenziswa ikakhulu kwizicelo ezixinzelelweyo ezomeleleyo ezinjengeetrasti, iikhreyithi kunye neebhlorho. I-ALTARY inika ukunganyangeki kokunyanzelwa okuqinisekileyo kwaye ithathe indawo ye-6061 kwizicelo ezininzi. Ukugqitywa kwesiphelo akulunganga kwaye ngenxa yoko akuyonto ithandekayo njengamanye ama-Afheti kuluhlu lwama-6000.

Ukuqina

I-6082 ibonelela ngoomatshini bokungasebenzi kakuhle. I-alloy isetyenziswa kwizicelo zesakhiwo kwaye ikhethwa kwi-6061.

Izicelo eziqhelekileyo

Izicelo zorhwebo kwezi zinto zobuchwephesha zibandakanya:

Izinto ezigxilisiweyo kakhuluOophahla

IiKhowsi zobisiIibhulorho

CranesI-ore skips

| Ukuqulunqwa kwekhemikhali ye-WT (%) | |||||||||

| Isilicon | Intsimbi | Ubhedu | Magnesium | Manganese | Chromium | Zinc | I-titanium | Abanye | I-aluminium |

| 0.7 ~ 1.3 | 0.5 | I-0,1 | 0.6 ~ 1.2 | 0.4 ~ 1.0 | I-0.25 | I-0.2 | I-0,1 | I-0.15 | Ibhalansi |

| Iipropathi eziqhelekileyo zoomatshini | ||||

| Umsindo | Ubukhulu (mm) | Tensile strength (MPA) | Unikeze Amandla (MPA) | I-elongwation (%) |

| T6 | 0.4 ~ 1.50 | ≥310 | ≥260 | ≥6 |

| T6 | > 1. 1.50 ~ 3.00 | ≥7 | ||

| T6 | > 3.00 ~ 6.00 | ≥10 | ||

| T6 | > 6.00 ~ 12.50 | ≥300 | ≥255 | ≥9 |

Izicelo

Inzuzo yethu

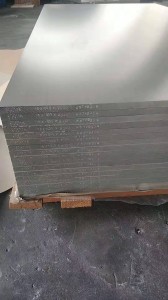

Uluhlu kunye nokuhanjiswa

Sinemveliso eyaneleyo kwisitokhwe, sinokunikezela ngezinto ezaneleyo kubathengi. Ixesha lokukhokela lingaphakathi kweentsuku ezisi-7 ze-stock materil.

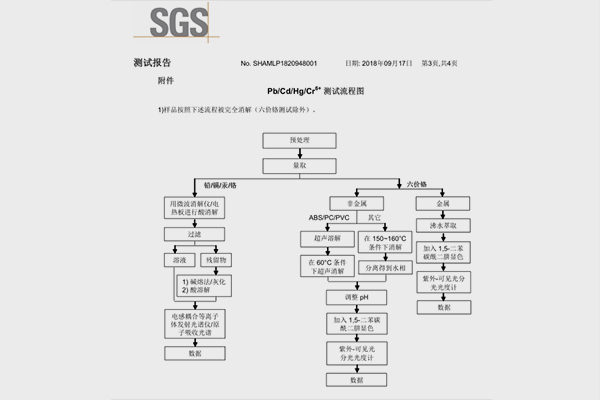

Umgangatho

Yonke imveliso ivela kumenzi omkhulu, sinokunikezela nge-MTC kuwe. Kwaye sinokubonelela ngengxelo yovavanyo lweqela lesithathu.

Isiko

Sinomatshini wokusika, ubukhulu besikolo bufumaneka.