I-ACP 5080 yokuphosa iPhepha le-Aluminiyam ye-Ultra

| Xa kuthelekiswa nezinto eziqhelekileyo | |||

| Ipleyiti yealuminiyam eqhelekileyo | Ultra-flat aluminiyam ipleyiti | ||

| Ukunyamezela ukutyeba | Ukuze usebenze ngokunyamezela ukutyeba okungqongqo, ipleyiti etyebileyo iyafuneka kwinkqubo enzima kunye nexesha elide ngaphambi kokusika. | Ukunyamezela ukutyeba kuphezulu kakhulu, akukho mfuneko yokusika ngokwahlukileyo, kwaye akukho mfuneko yokugaya umphezulu, kunokunciphisa kakhulu iindleko kunye nexesha. | |

| Ukuchaneka okucaba | Ipleyiti etyebileyo eneflethi echanekileyo ayinyusi nje kuphela iindleko zokusika, kodwa ikwafuna ukusetyenzwa kwipleyiti etyebileyo. | Ngokutyabeka okugqwesileyo, ubuninzi nge-0.05mm/㎡, kunokunciphisa iindleko zokusika kunye nexesha lokucubungula kunye nomvuzo. | |

| Ukunwebeka okushiyekileyo | Ibilutshintsho olulula ngexesha lokusetyenzwa ngenxa yokuqina okukhulu okushiyekileyo, kuya kongeza inkqubo yokukhutshwa kwe-elastic annealing. | Nge-deformation ephantsi emva kwenkqubo, akukho mfuneko yokukhulula i-elastic yangaphakathi, ukulinganisa kunye nolunye unyango. Inokunciphisa iindleko kunye nokuphucula ukusebenza kakuhle. | |

Usetyenziso

IMVELISO YE-ELECTRONIC

Isetyenziswe kwiphaneli ye-aluminium substrate yesekethe yeemveliso zombane okanye oomatshini. Umahluko we-flatness yepaneli ye-aluminium substrate kwinqanaba ngalinye lenkqubo yokuvelisa, kubandakanywa izinto eziluhlaza. Kulula ukubangela ukungachaneki kwemilinganiselo ye-stamping ngenxa yokugoba kwepleyiti ye-aluminium eqhelekileyo ngexesha lenkqubo yesitampu, eyandisa iindleko zokuvelisa, i-Ultra-flat plate inciphisa kakhulu iindleko zemveliso.

PRECISION Instrument

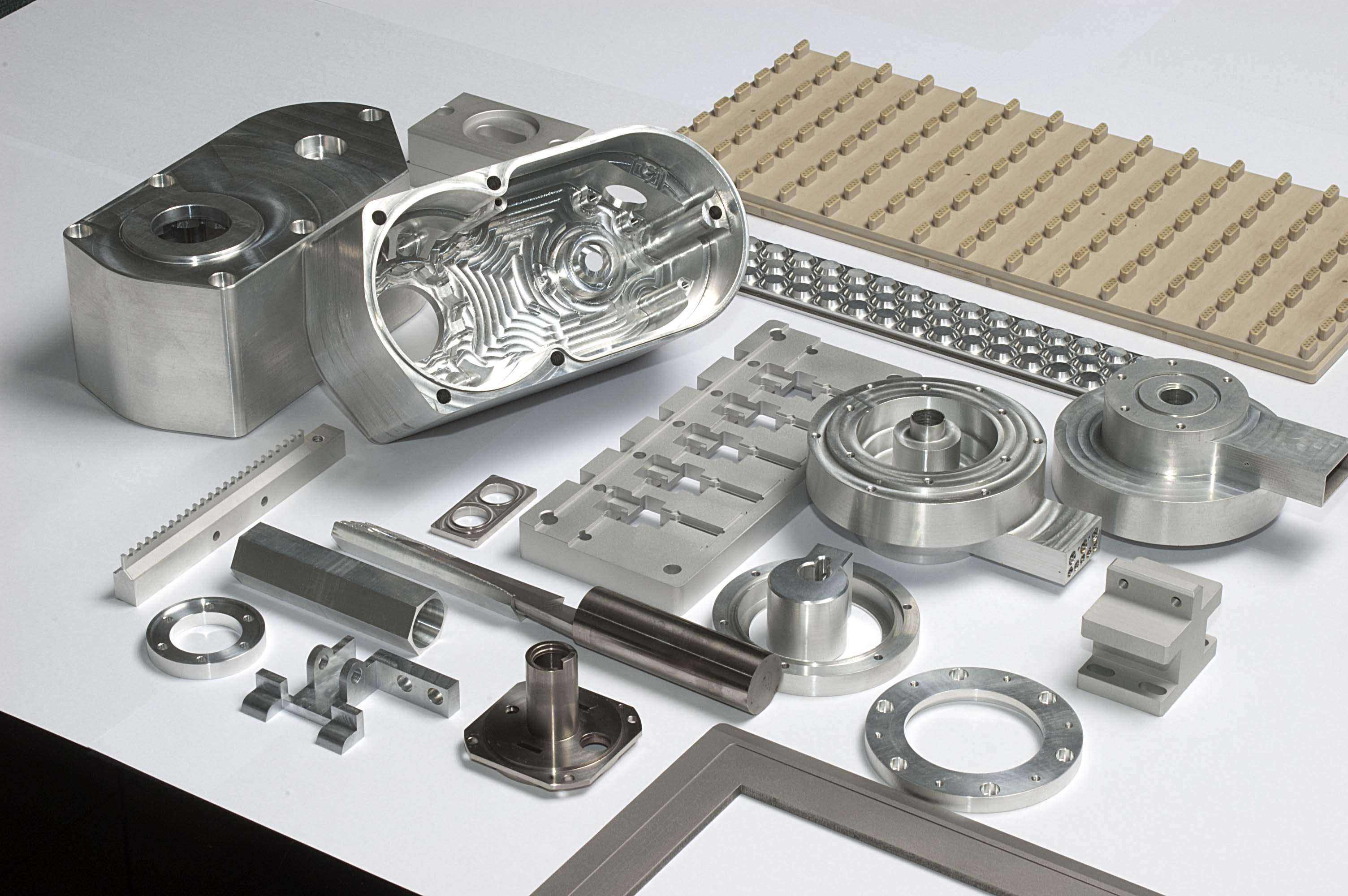

Iipleyiti ze-aluminiyam ezine-Ultra-flatness zisetyenziswa kakhulu kwizixhobo ezichanekileyo, ezinokuthi zisetyenzwe zibe yi-soft pack fixtures yebhetri, i-3C ethambileyo yepakethe ye-digital ye-bettery fixture fixture (i-assembly) izixhobo, kunye nokulungiswa kwebhetri okuchanekileyo, ngakumbi kwintsimi yamandla amatsha.

UKUSEBENZA

Iimpawu zeplate ye-aluminium ye-ultra-flatness zenza iinkampani ezininzi ze-machining zizimisele ukuyikhetha xa zilungisa iindawo ezichanekileyo, ezinokuqinisekisa kakuhle ubungakanani kunye nokuchaneka kwemveliso egqityiweyo emva kokulungiswa, kunye nokunciphisa kakhulu izinga le-scrap ngexesha lokucubungula, kunye nokuphucula izinga elifanelekileyo leemveliso ezigqityiweyo.

EZINYE IZICELO

Ezinye izicelo ezifana ukupakishwa koomatshini iqonga, iqonga oomatshini automated, 3D umshicileli, izixhobo zokuhlola, ipaneli eqhelekileyo, umtshina, irobhothi ingalo chassis, etc. Iiphaneli ze-Ultra-flat zinokusombulula imveliso engafanelekanga ebangelwa yi-flatness engachukumisi umgangatho, ngoko ke zithandwa kakhulu kwintsimi yoshishino.

Inzuzo Yethu

Uluhlu kunye nokuhanjiswa

Sinemveliso eyaneleyo kwisitokhwe, sinokunikela ngezinto ezaneleyo kubathengi. Ixesha lokukhokela linokuba phakathi kweentsuku ezi-7 kwizinto eziphathekayo.

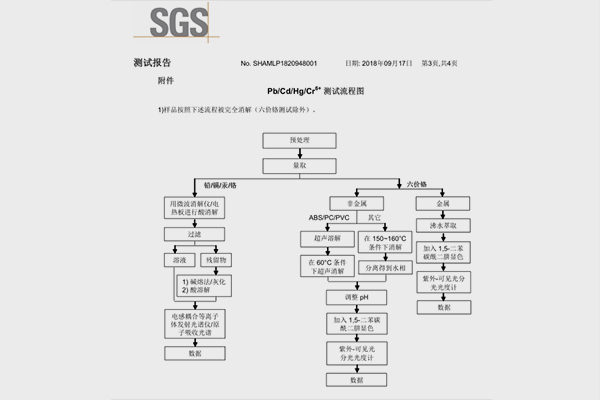

Umgangatho

Zonke imveliso zivela kumvelisi omkhulu, sinokunikezela ngeMTC kuwe. Kwaye sinokunikezela ngengxelo yovavanyo lweQela leSithathu.

Isiko

Sinomatshini wokusika, ubukhulu besiko buyafumaneka.