I-1060 ye-Aluminiyam ye-Aluminiyam ye-Aluminiyam ye-Plate ye-Corrosion Resistance i-Aluminiyam yePhepha 1060

I-Aluminiyam / i-Aluminiyam i-1060 i-alloy ingamandla aphantsi kunye ne-Aluminiyam ecocekileyo / i-alloy ye-Aluminiyam eneempawu zokuxhathisa ukubola.

I-Aluminiyam / i-Aluminiyam i-1060 i-alloy inokuqiniswa kuphela ekusebenzeni okubandayo. Ubushushu be-H18, i-H16, i-H14 kunye ne-H12 imiselwe ngokusekelwe kubungakanani bomsebenzi obandayo onikezelwe kule alloy.

I-Aluminiyam / i-Aluminiyam i-1060 i-alloy ilinganiswe ngokufanelekileyo ukuya kwi-machinability embi, ngakumbi kwiimeko zomsindo othambileyo. I-machinability iphuculwe kakhulu kwiimeko ezinzima (ezibandayo). Ukusetyenziswa kwezithambiso kunye nokuba zizixhobo zentsimbi ezinesantya esiphezulu okanye i-carbide ziyacetyiswa kule alloy. Okunye ukusika le alloy nako kunokwenziwa yomile.

I-Aluminiyam / i-Aluminiyam 1060 i-alloy isetyenziswa ngokubanzi ekwenzeni iimoto zetanki zikaloliwe kunye nezixhobo zekhemikhali.

| Ukwakheka kwemichiza WT(%) | |||||||||

| Isilicon | Intsimbi | Ubhedu | Magnesium | IManganese | Chromium | Zinc | I-Titanium | Abanye | Aluminiyam |

| 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | 99.6 |

| Iipropati zoomatshini eziqhelekileyo | ||||

| Ukucaphuka | Ukutyeba (mm) | Tensile strength (Mpa) | Unikeze Amandla (Mpa) | Elongation (%) |

| H112 | >4.5–6.00 | ≥75 | - | ≥10 |

| >6.00–12.50 | ≥75 | ≥10 | ||

| >12.50–40.00 | ≥70 | ≥18 | ||

| >40.00~80.00 | ≥60 | ≥22 | ||

| H14 | >0.20–0.30 | 95~135 | ≥70 | ≥1 |

| >0.30–0.50 | ≥2 | |||

| ~0.50~0.80 | ≥2 | |||

| ~0.80~1.50 | ≥4 | |||

| >1.50–3.00 | ≥6 | |||

| 3.00 ~ 6.00 | ≥10 | |||

Usetyenziso

Inzuzo Yethu

Uluhlu kunye nokuhanjiswa

Sinemveliso eyaneleyo kwisitokhwe, sinokunikela ngezinto ezaneleyo kubathengi. Ixesha lokukhokela linokuba phakathi kweentsuku ezi-7 kwizinto eziphathekayo.

Umgangatho

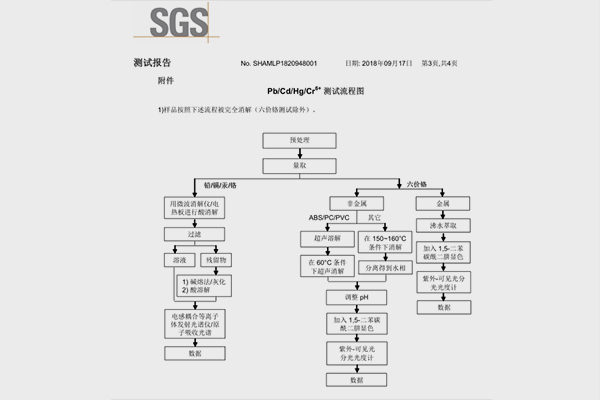

Zonke imveliso zivela kumvelisi omkhulu, sinokunikezela ngeMTC kuwe. Kwaye sinokunikezela ngengxelo yovavanyo lweQela leSithathu.

Isiko

Sinomatshini wokusika, ubukhulu besiko buyafumaneka.