Munguva yekuonekwa kwehupfumi, zvigadzirwa zvakanaka zvinowanzozivikanwa nevanhu vazhinji, uye izvo zvinonzi manyorero zvinowanikwa kuburikidza nekuona uye kubata. Nekuda kwekunzwa uku, kurapwa kwepamusoro chinhu chakanyanya kutsoropodza. Semuenzaniso, ganda rekomputa yelaptop yakagadzirwa neyakagadzirwa nealuminium Alloy kuburikidza neCnc Kugadziriswa kwechimiro, uyezve kupukuta, zviyero zvepamusoro uye mamwe maitiro mazhinji anogadziriswa kuti agadzikane nesimbi yerudzi uye tekinoroji. Aluminium Alloy iri nyore kuita, ine nzira dzakapfuma dzekurapa dzekurapa, uye yakanaka maonero. Inoshandiswa zvakanyanya mumapepa, mbozhanhare, makamera uye zvimwe zvigadzirwa. Iyo inowanzosanganiswa nemaitiro ekurapa ekurapa akadai sekupukuta, kutsvaira, sandbingaperi, yakakwirira-gomba rekucheka uye inogadzira kuti chigadzirwa chive chinhu chakasiyana.

ChiPolish

Maitiro ekupukuta anonyanya kuderedza kuomarara kwesimbi kuburikidza nemakemikari ekupukuta kana kuunganidza kururamisa kwejimpeni

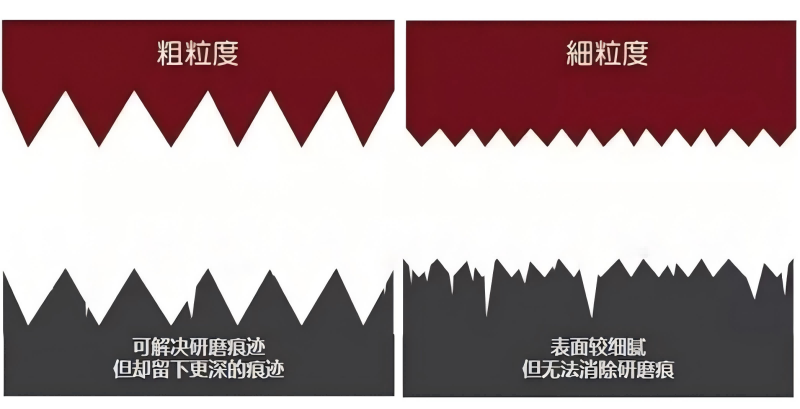

Mechancal polishi inoshandisa sandipaper kana kupukuta mavhiri kuderedza kuoma uye kugadzira simbi yepasi uye inopenya. Nekudaro, kuomarara kweAluminium Alloy hakuna kukwirisa, uye kushandisa yakagadziriswa-yakagadziriswa yekukuya uye kupukuta zvinhu zvichasiya mitsara yakadzika yekukwevera. Kana zviyo zvakanaka zvashandiswa, iyo nzvimbo yakanakisa, asi kugona kubvisa mitsara yekugaya yakaderedzwa kwazvo.

Kemical polishing chirongwa cheElectrochemical icho chinogona kutariswa sekudzosera Electroplating. Iyo inobvisa tete yakaonda yezvinyorwa pane iyo simbi pamusoro, ichisiya yakatsiga uye ultra-yakachena-yakachena-ine yunifomu gloss uye hapana mitsara yakanaka inoonekwa panguva yekupukuta kwemuviri.

Muchiripo chekurapa, kupopotera chemakemikari kunogona kuita kuti zvishandiso zvekuvhiya zviri nyore kuchenesa uye kuuraya. Mumidziyo yemagetsi yakadai sefiriji uye yekugeza michina, kushandiswa kwemakemikari zvigadzirwa zvinogona kuita kuti zvikamu zvive zvekare uye kuve nechitarisiko chakajeka. Iko kushandiswa kwemakemikari kupukuta mune kiyi ndege zvinhu kunogona kuderedza kupokana kupokana, kuve kwakanyanya simba-kwakachengeteka uye kwakachengeteka.

Sandbing

Zvigadzirwa zvakawanda zvemagetsi zvinoshandisa tekinoroji yekushandisa kwechigadzirwa kuti chigadzirwa chigadzirwa charwo chichiwedzera zvakanyanya matte matte kubata, zvakafanana negirazi rakacheneswa. Iyo Matte zvinyorwa zvinongedzo uye zvakatsiga, kugadzira iyo yakaderera-kiyi uye inogara tsika yechigadzirwa.

Sandbebaration inoshandisa mhepo yakamanikidza simba rekupfira zvinhu, senge sanda ore sand, jecha regungwa, ethangu, achichinja manhamba ealuminium yeiyo aluminium Zvikamu zveAlloy, kuvandudza kupokana kwekuneta kwezvikamu, uye kuwedzera kuderedza pakati pezvinyorwa zvekutanga kwezvikamu uye zvipfuyo, izvo zvinobatsira mukugadzika kwe kuunganidza uye nekukasira uye kushongedza kwekuchera.

Iyo sandbos yekuseri kwekurapa maitiro maitiro ekukurumidza uye akanyanya kunyatsochenesa nzira. Iwe unogona kusarudza pakati pezvakasiyana zvimiro zvekugadzira dzakasiyana-siyana dzakaipa pamusoro peiyo aluminium alloy zvikamu.

Kutsva

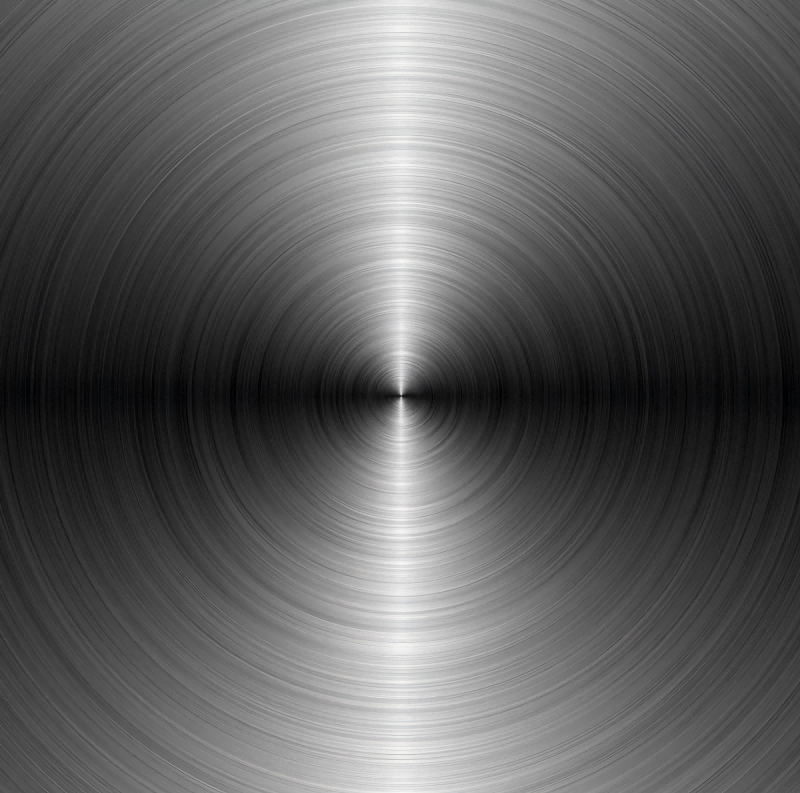

Brush inozivikanwa kwazvo mugadziriro yechigadzirwa, yakadai sekunyora zvinyorwa uye mahedhifoni muzvigadzirwa zvemafuta, mafiriji uye mhepo inonatsa mune zvigadzirwa zveimba, uye inoshandiswawo mumatare emota. Iyo Center console ine bhururu panel inogonawo kuwedzera kunaka kwemota.

Dzokorora mitsara inodonhedza pane iyo aluminium ndiro ine sandpaper inogona kuratidza zvakajeka glik yemuchadenga Zvinoenderana nezvinodiwa zvekushongedza, zvinogona kuitwa mumitsetse yakatwasuka, mitsara yakasarudzika, mitsara yakatsva, nezvimwe.

Iyo microwave oven iyo yakakunda iyo kana mubairo usingashandise kutsvaira pamusoro, iyo ine yakasimba uye yemweya runako, inosanganisa fashoni uye tekinoroji.

Yakanyanya Gloss Kugaya

Iyo yakakwira gloss yekugaya inoshanda inoshandisa mushini wakanyatsonongedzera kucheka zvikamu uye kugadzirisa nzvimbo dzenzvimbo pamusoro pechigadzirwa. Dzimwe nhare dzine mbozhanhare dzine masimbi avo akanyorwa nedenderedzwa rekusimbisa chamfers, uye zvimwe zvidiki zvesimbi zvevhu zvine chimwe kana chakayera zvakadzama zvakanyudzwa kuti uwedzere kupenya kwechigadzirwa, izvo zvakajeka.

Mumakore achangopfuura, mamwe mafurati embeu esimbi yakakwira akatora chigaro chegwenzi hombe, uye maitiro echidhirowa uye ekusuka anoita TV yakazara nefashoni uye tekinoroji.

Anodizing

Muzhinji, zvikamu zvealuminium hazvina kukodzera Electroplating nekuti zvikamu zveAluminium zviri nyore kwazvo kuumba firimu renzou paokisijeni, iyo ichakanganisa zvakanyanya simba rekubatanidza reElectroplating layer. Anodizing anowanzoshandiswa.

Anodizing anoreva nezve electrochemical oxidation yesimbi kana alloys. Mumamiriro ezvinhu chaiwo uye chiitiko chekushandisa zvazvino, chikamu chealuminium oxide firimu chinoumbwa pamusoro pechikamu, chinovandudza hupfumi hwepamusoro uye hwapfeka kupokana kwechikamu uye nekuwedzera kupokana kwekoramu.

Mukuwedzera, kuburikidza neyekushambadzira huwandu hwehuwandu hweMicropores mufirimu mutete, pamusoro pechikamu chinogona kuve chakaringana uye chakajeka colors, chinjana kuita kwemavara uye kuwedzera runako rwechigadzirwa chechigadzirwa.

Kutumira Nguva: Sep-05-2020