Aluminum alloys play a crucial role in the semiconductor industry, with their wide-ranging applications having a profound impact. Here is an overview of how aluminum alloys influence the semiconductor industry and their specific applications:

I. Applications of Aluminum Alloys in Semiconductor Manufacturing

1. Structural Materials for Equipment:

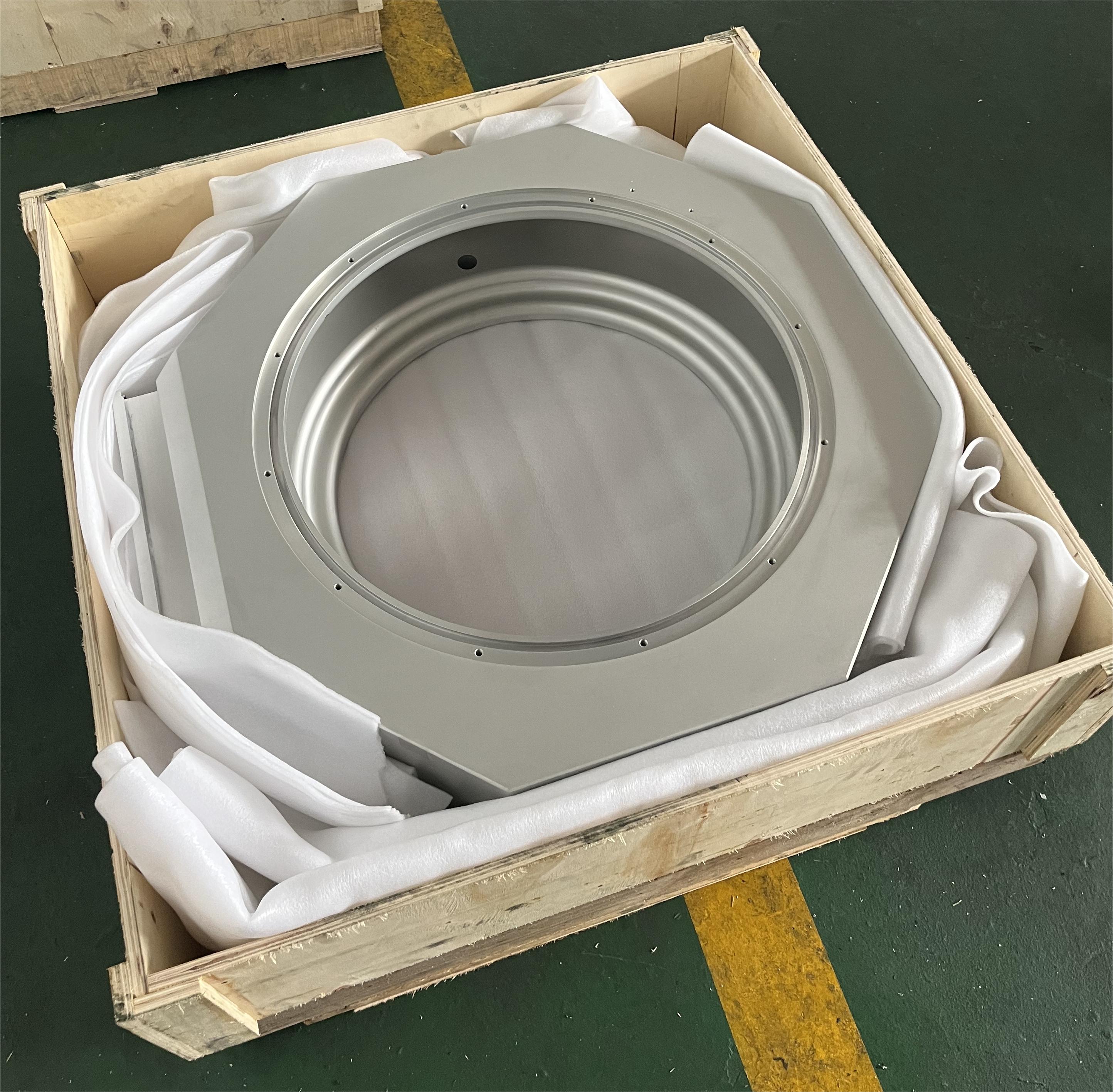

- Vacuum Chambers: Aluminum alloys are used to manufacture vacuum chambers in semiconductor equipment due to their excellent mechanical properties and thermal conductivity. These chambers need to withstand high temperatures and pressures while maintaining a high vacuum environment.

- Supports and Frames**: Aluminum alloys, being lightweight yet strong, are widely used to make supports and frames for equipment, reducing overall weight and increasing operational flexibility.

2. Heat Dissipation Components:

- Heat Sinks: Aluminum alloys, known for their excellent thermal conductivity, are commonly used to make heat sinks in semiconductor equipment, helping to quickly dissipate heat and ensure stable operation of the equipment.

- Cooling Plates: Aluminum alloy cooling plates are used in the cooling systems of semiconductor equipment to effectively lower temperatures, enhancing the reliability and lifespan of products.

3. Wafer Handling Devices:

- Robotic Arms: Robotic arms used for transferring wafers during semiconductor manufacturing are often made of aluminum alloys. The lightweight and high-strength properties of aluminum alloys make them an ideal choice, ensuring precise and rapid wafer transfer.

II. Applications of Aluminum Alloys in Semiconductor Materials

1. Metal Interconnects:

- Aluminum Interconnects: Aluminum and its alloys are widely used as interconnect materials within chips. Despite copper interconnects gradually replacing aluminum in recent years, aluminum remains significant in certain applications due to its good conductivity and cost-effectiveness.

2. Packaging Materials:

- Aluminum Alloy Packaging: Aluminum alloys are used in semiconductor device packaging to provide effective electrical connections and mechanical protection while offering good thermal performance to ensure the reliability of devices during high-efficiency operation.

III. Advantages of Aluminum Alloys in the Semiconductor Industry

1. Lightweight and High Strength:

- The lightweight nature of aluminum alloys reduces the overall weight of equipment and components, enhancing manufacturing and operational efficiency.

2. Excellent Thermal Conductivity:

- Their excellent thermal conductivity makes aluminum alloys perform well in heat dissipation applications, ensuring semiconductor equipment maintains suitable temperatures during high-efficiency operations.

3. Good Machinability:

- Aluminum alloys are easy to machine and form, meeting the precise processing requirements of semiconductor equipment and components.

4. Corrosion Resistance:

- The corrosion resistance of aluminum alloys gives them a longer lifespan in the harsh environments of semiconductor manufacturing, reducing the frequency of equipment maintenance and replacement.

IV. Future Prospects

1. Material Improvements:

- With the advancement of semiconductor technology, the performance requirements for materials are continuously increasing. The composition and processing of aluminum alloys will be continually improved to meet higher conductivity, thermal conductivity, and mechanical strength demands.

2. Development of New Applications:

- Emerging semiconductor technologies (such as quantum computing and flexible electronics) may bring new demands for aluminum alloy materials. Research and development of new aluminum alloy materials and applications will be an important direction in the future.

3. Environmental Protection and Sustainability:

- The recyclability and reuse characteristics of aluminum alloys give them advantages in environmental protection and sustainability. In the future, the semiconductor industry will place greater emphasis on material recycling and environmental impact, promoting the application and development of aluminum alloys.

In summary, aluminum alloys have a significant impact on the semiconductor industry, playing a key role in equipment manufacturing, material applications, and technological development. As technology progresses and demands change, the applications of aluminum alloys in the semiconductor industry will continue to expand and deepen.

Post time: Jul-05-2024