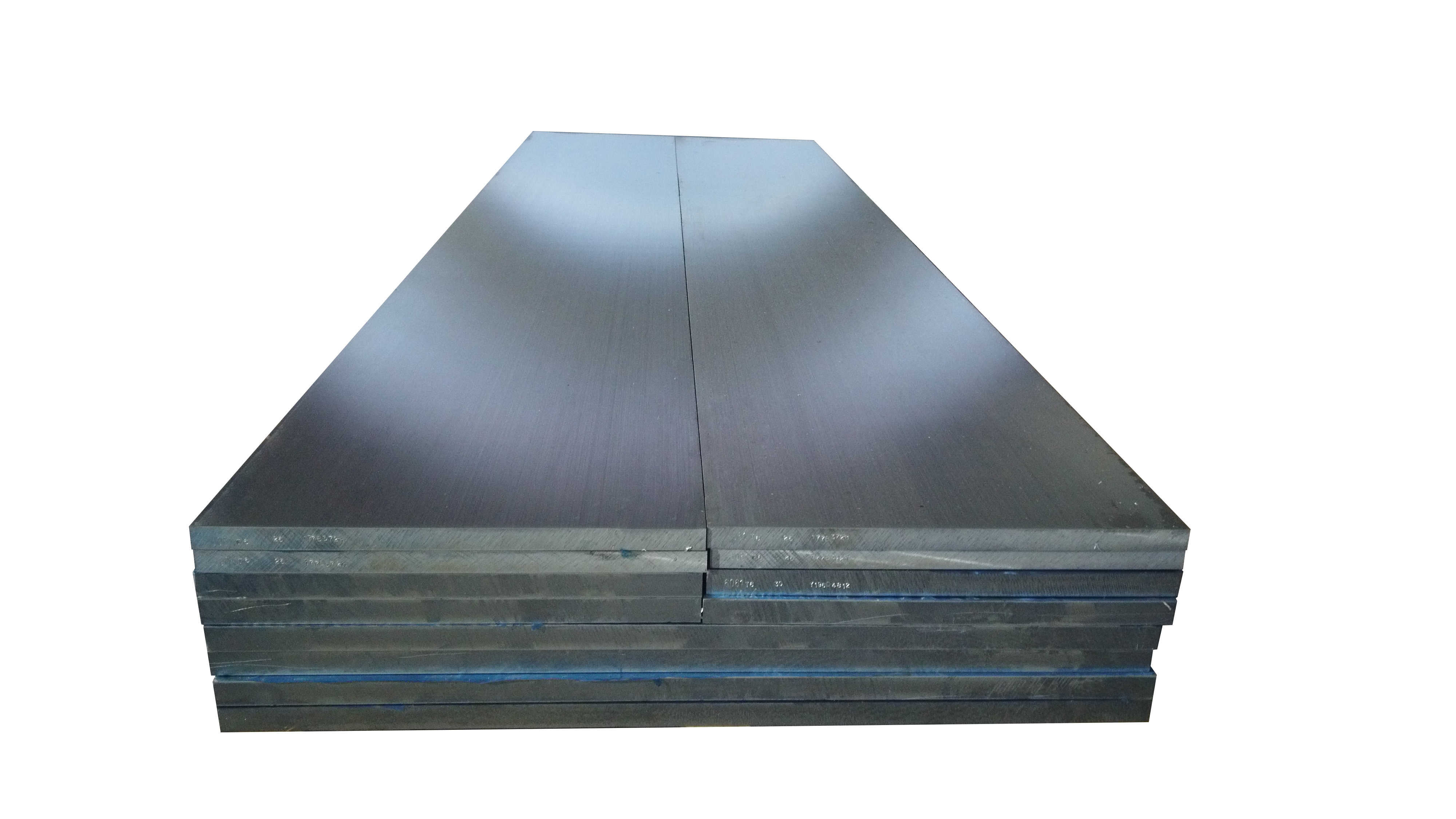

Aluminium 6061 Allay ASTM B209 6061 T6 P651 Plate Street

6000 Usoro usoro almunium na-ahụ maka magnesium na silicon. Alloy 6061 bụ otu n'ime alloys kachasị na usoro 6000. O nwere ezigbo ọrụ eji arụ ọrụ, ọ dị mfe igwe, ọ bụ welduble, ma sie ike, ma ọ bụghị ike dị elu nke 2000 na 7000 nwere ike iru. Ọ nwere ezigbo nguzogide na-eguzogide na ezigbo werddọbis nke dị mma n'agbanyeghị na mbelata ike na mpaghara Wald. Ngwongwo igwe ihe nke 6061 na-adabere nke ukwuu na iwe iwe, ma ọ bụ ọgwụgwọ ọkụ, nke ihe ahụ. N'ikwu banyere 2024 alloy, a na-arụ ọrụ mfe ọrụ ma na-eguzogide corrosion ọbụna mgbe elu ahụ.

Pịnye 6061 aluminom bụ otu n'ime almunium aluminom na-ejikarị. Weld-ike na nhazi ya na-eme ka ọ dị mma maka ọtụtụ ngwa ebumnuche. Ike ya dị elu na nguzogide corrosion ịgbazinye ụdị 6061 alloy bara uru na ụlọ ọrụ, owuwu na ngwa ụgbọala.

| Ihe mejupụtara kemịkal wt (%) | |||||||||

| Silicon | Igwe | Kopa | Magnesium | Manganese | Chromium | Zink | Tibanium | Ndi ozo | Aluminom |

| 0.4 ~ 0.8 | 0.7 | 0.15 ~ 0.4 | 0.8 ~ 1.2 | 0.15 | 0.05 ~ 0.35 | 0.25 | 0.15 | 0.15 | Itule |

| Ngwongwo ndi oru | ||||

| Obioku | Okpurukpu (mm) | Ike ọdụdọ (MPA) | Runnwe ike (MPA) | Elongation (%) |

| T6 | 0.4 ~ 1.5 | ≥290 | ≥240 | ≥6 |

| T6 | 1.5 ~ 3 | ≥290 | ≥240 | ≥7 |

| T6 | 3 ~ 6 | ≥290 | ≥240 | ≥10 |

| T651 | 6 ~ 12.5 | ≥290 | ≥240 | ≥10 |

| T651 | 12.5 ~ 25 | ≥290 | ≥240 | ≥8 |

| T651 | 25 ~ 50 | ≥290 | ≥240 | ≥7 |

| T651 | 50 ~ 100 | ≥290 | ≥240 | ≥5 |

| T651 | 100 ~ 150 | ≥290 | ≥240 | ≥5 |

Ngwa

Aircraft Air

Achekwara nchekwa

Okpomoku

Uru anyị

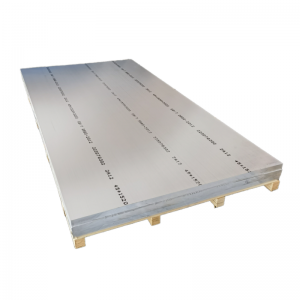

Ngwaahịa na nnyefe

Anyị nwere ngwaahịa zuru ezu na ngwaahịa, anyị nwere ike ị nweta ndị ahịa zuru ezu. Oge ndu nwere ike ịbụ n'ime ụbọchị asaa maka ngwaahịa.

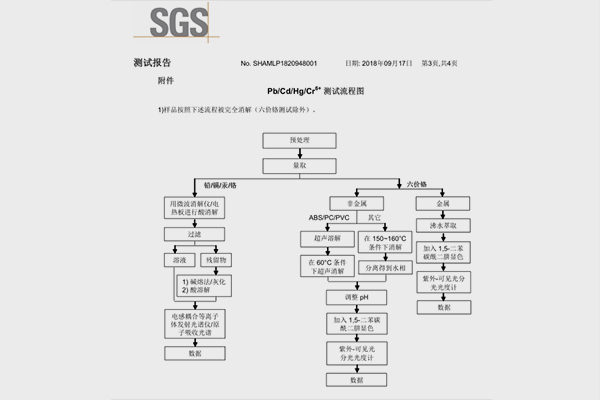

Mma

Ngwaahịa niile sitere na onye nrụpụta kachasị, anyị nwere ike ịnye gị MTC. Anyị nwekwara ike inye akụkọ ule nke ọzọ.

Omenaala

Anyị nwere igwe, nha omenala dị.