GB-GB3190-2008: 6061

Asalin Amurka-Astm-B209: 6061

Asalin Turai-en-aw: 6061 / Almg1sicu

606 Alumum Alloyabu ne mai zafi da gaske, tare da kyawawan filastik, weldability, sarrafawa da matsakaici aiki, ana iya amfani da launi iri-iri, ana iya fasalta launi a cikin enamel , dace da kayan gini kayan ado. Ya ƙunshi karamin adadin CU kuma don haka ƙarfin ya fi 606, amma lokacin jin daɗin yana sama da 603. Bayan tashin hankali ba zai yiwu ba, lokacin da aka sake amfani da shi, kuma ana buƙatar maganin sake yin tsufa .6061 Manyan abubuwan alloli na aluminum sune silicon, silicon, wanda ke samar da yanayin Mg2si. Idan ya ƙunshi wani adadin Manganese da Chromium, yana iya kawar da tasirin baƙin ƙarfe; wani lokacin ƙara yawan ƙarfe ko zinc wani lokaci ƙara don rage ƙarfin jingina da ƙananan kayayyaki Don kashe illolin tasirin titanium da baƙin ƙarfe akan hanya; Zirconium ko titanium na iya tsaftace hatsi da sarrafa tsarin recrystallization; Don haɓaka aikin sarrafawa, jagora da bismuth za'a iya ƙara. Mg2sud m narkar a cikin aluminum, saboda alloy yana da aikin wucin gadi.

606 Alumum Alloy kyakkyawan kaddarorin, akasin da ya hada da wadannan fannoni:

1. Babban ƙarfi: 606 Silnum Alumanum yana da ƙarfi mai ƙarfi bayan da ya dace da yanayin da ya dace zai iya kaiwa sama da 300 MPa, yana da ƙarancin matsakaici na aluminum.

2. Kyakkyawan aiki: 606 Alumumilum alloy mai kyau Macoying, mai sauƙin yanka, tsari da waldi, kamar milling, hinging, stamping, hade, stam, da sauransu.

3. Kyakkyawan lalata juriya: 606 aluminum aluminium yana da juriya na lalata jiki, kuma yana iya nuna kyawawan juriya na lalata a cikin yawancin mahalli, musamman a cikin mahalli kamar ruwa kamar bakin ruwa.

4. Haske: aluminium duka nauyi nauyi, 601 aluminium aloy mai sauƙi ne, kamar yadda ake bukata da kuma masana'antar mota.

5. Kyakkyawan yanayin zafi da lantarki: 606 aluminum alayyaum yana da kyakkyawan thermal da kuma abubuwan lantarki, kamar inforewa zafin wuta.

6. Dalili mai ban sha'awa: 606 aluminum aluminium yana nuna kyakkyawan walwala mai kyau, kuma yana da sauƙin welding tare da wasu kayan, kamar tig walda, da sauransu, da sauransu, da sauransu, da sauransu.

6061 GASKIYA SANARWA

1. Toparfin ƙarfin ƙarfi: tenarfin tenarfin 6061 aluminum aloy na iya kaiwa 280-310 MPa, kuma ya fi girma a cikin jihar T6, kai ga matsakaicin darajar da ke sama.

2. Inganta ƙarfi: yawan amfanin ƙasa da ƙarfi na 6061 aluminum aloy yana kusan kusan 240 MPa, wanda ya fi girma a jihar T6.

3. Exlongation: elongation aluminum na 6061 aluminium aloy yana tsakanin 8 zuwa 12%, wanda ke nufin wasu yankewa lokacin shimfiɗa.

4. Hardness: Hardness: 606 601 Alumanum Alumum Alumy Horning yawanci tsakanin 95-110 HB, babban ƙarfi, yana da ƙarfi, yana da wani sandar juriya.

5.

Wadannan sigogi masu amfani da na inji zasu bambanta da bambancin mahaɗan zafi da kuma tsarin sarrafawa. Gabaɗaya, ƙarfin da wuya za a iya inganta bayan da ya dace da kwanciyar hankali (kamar T6 magani) na606 Alumum Alloy, don ta inganta kaddarorinta na inji. A aikace, ana iya zaɓar kasashen da suka dace da ruwan zafi gwargwadon takamaiman buƙatun don cimma mafi kyawun aikin injiniya.

Tsarin magani mai zafi:

Saurin zafin jiki na sauri: Hajewa zazzabi 350 ~ 410 ~, tare da ingancin kauri daga cikin 30 ~ 120min, iska ko sanyaya ruwa.

Babban zazzabi an bayyana: yawan zafin jiki shine 350 ~ 500 ℃, lokacin rufin shine 6mm, shigarwar zafi, iska tana sanyi.

Zazzabi mai ƙarancin zafin jiki: yawan zafin jiki shine 150 ~ 250 ℃, da kuma rufin da ruwa shine 2 ~ 3h, tare da iska ko sanyaya ruwa.

6061 na yau amfani da aluminum ado:

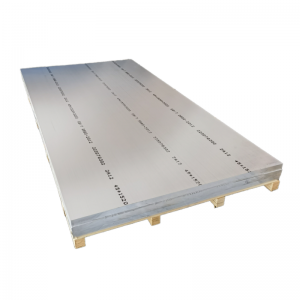

1. Aikace-aikacen farantin da bel an yalwaci a cikin ado, marufi, sufuri, lantarki, jirgin ruwa, jirgin sama da sauran masana'antu.

2. Ana amfani da Aeraspace don sinad da ake amfani da fata don yin fatar jirgin sama, FuseLage firam, masu jujjuyawa, panels mai, da sauransu, da sauransu.

3. Ana amfani da kayan aikin kayan sufuri a cikin mota, motocin jirgin ƙasa, kayan jirgin sama, masu hawa, masu hawa, kayan jirgi, ƙafafun jiki, ƙafafun da kayan jirgin.

4. Aluminum Aluman-Aluminum na iya don kunshin shine a cikin hanyar takardar mai haɗi, wanda aka yi da gwangwani, katako, koguna. Na'ura da aka yi amfani da shi a cikin abubuwan sha, abinci, kayan kwalliya, kwayoyi, sigogin masana'antu da sauran marufi.

5. Alumum don bugu anyi amfani dashi don sanya farantin ps, kayan aluminum plate sabon abu ne na masana'antu, ana amfani da shi don bugawa da bugawa.

6. Alumumum aluminum reilum don gina adon ado, wanda aka yi amfani da shi sosai ga kyawawan dadiyyarta juriya, isasshen ƙarfin aiki da kuma aikin waldi. Kamar kowane nau'in gine-ginen gini da windows, bangon labulen a kan aluminium, farantin labulen, maƙallan labulen aluminium, da sauransu.

7. Alumum na kayan aikin gida ana amfani da su a yawancin busassun busassun abubuwa, wayoyi, masu gudanar da kaya, kayan aikin lantarki, na cirewa, yansayen iska, igiyoyi da sauran filayen.

La'akari da abubuwan da ke sama,606 Alumum AlloyAna amfani da shi sosai a cikin Aerospace, masana'antar jigilar kaya, masana'antar mota, injiniyan gini da sauran filayen. A cikin aikace-aikacen aikace-aikace, silinum aluminium ado tare da ƙasashen da aka yi amfani da zafi na zafi a gwargwadon takamaiman bukatun don cimma kyakkyawan aikin.

Lokaci: Jun-25-2024