7075 T6 T651 Aluminum Tube Pipe

Alloy 7075 aluminum are the outstanding member of the 7xxx series and remains the baseline among the highest strength alloys available. Zinc is the primary alloying element giving it strength comparable to steel. Temper T651 possesses good fatigue strength, fair machinability, resistance welding and corrosion resistance ratings. Alloy 7075 in temper T7x51 has superior stress corrosion resistance and replaces the 2xxx alloy in the most critical applications.

7075 aluminum alloy is one of the strongest aluminum alloys available, making it valuable in high-stress situations. Its high yield strength (>400 MPa) and its low density make the material a fit for applications such as aircraft parts or parts subject to heavy wear. While it is less corrosion resistant than other alloys (such as 5083 aluminum alloy, which is exceptionally resistant to corrosion), its strength more than justifies the downsides.

|

Chemical Composition WT(%) |

|||||||||

|

Silicon |

Iron |

Copper |

Magnesium |

Manganese |

Chromium |

Zinc |

Titanium |

Others |

Aluminum |

|

0.4 |

0.5 |

1.2~2 |

2.1~2.9 |

0.3 |

0.18~0.28 |

5.1~5.6 |

0.2 |

0.05 |

Balance |

|

Typical Mechanical Properties |

||||

|

Temper |

Wall Thickness (mm) |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

| T6/T651/T6511 | ≤6.30 |

≥540 |

≥485 |

≥7 |

| >6.30~12.50 |

≥560 |

≥505 |

≥7 |

|

| >12.50~70.00 |

≥560 |

≥495 |

≥6 |

|

| T73/T7351/T73511 | 1.60~6.30 |

≥470 |

≥400 |

≥5 |

| >6.30~35.00 |

≥485 |

≥420 |

≥6 |

|

| >35.00~70.00 | ≥475 | ≥405 | ≥8 | |

Applications

Aircraft Wing

Highly stressed aircraft parts

Aircraft manufacturing

Our Advantage

Inventory and Delivery

We have enough product in stock, we can offer enough material to customers. The lead time can be within 7 days for stock materil.

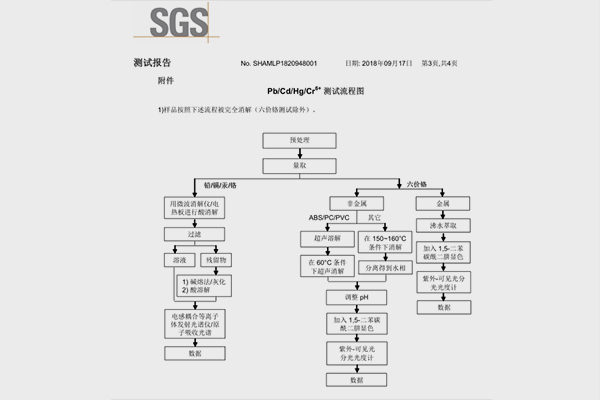

Quality

All the product are from the biggest manufacturer, we can offer the MTC to you. And we can also offer Third-Party test report.

Custom

We have cutting machine, custom size are available.