5083 Aluminum Round Bar Marine Grade 5083 Rod for Ship-Building

5083 aluminium alloy is well known for its exceptional performance in the most extreme environments. The alloy displays high resistance to both seawater and industrial chemical environments.

With good overall mechanical properties, 5083 aluminium alloy benefits from good weldability and retains its strength after this process. The material combines excellent ductility with good formability and performs well in low-temperature service.

Highly corrosion resistant, 5083 is largely used around salt water for building ships and oil rigs. It maintains its strength in extreme cold, so it's also used to make cryogenic pressure vessels and tanks.

|

Chemical Composition WT(%) |

|||||||||

|

Silicon |

Iron |

Copper |

Magnesium |

Manganese |

Chromium |

Zinc |

Titanium |

Others |

Aluminum |

|

0.4 |

0.4 |

0.1 |

4~4.9 |

0.4~1.0 |

0.05~0.25 |

0.25 |

0.15 |

0.15 |

Remainder |

|

Typical Mechanical Properties |

|||||

|

Temper |

Thickness (mm) |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Hardness (HBW) |

| O | ≤200.00 |

270~350 |

≥110 |

≥12 |

70 |

| H112 | ≤200.00 | ≥270 | ≥125 |

≥12 |

70 |

Applications

Ship Construction

Oil Rigs

Storage Tanks

Our Advantage

Inventory and Delivery

We have enough product in stock, we can offer enough material to customers. The lead time can be within 7 days for stock materil.

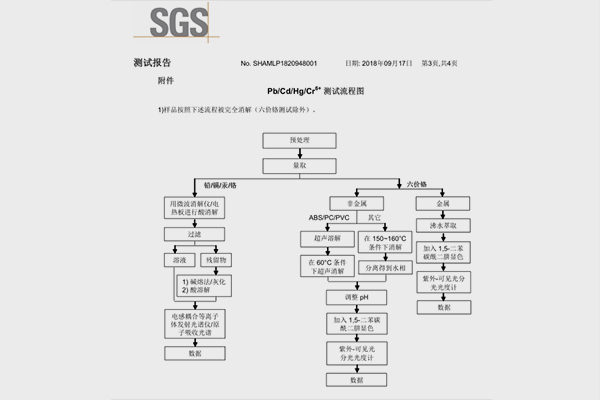

Quality

All the product are from the biggest manufacturer, we can offer the MTC to you. And we can also offer Third-Party test report.

Custom

We have cutting machine, custom size are available.