2021 High quality Aluminum 5005 - ACP 5080 Precision Aluminum Plate Ultra Flatness Surface – Miandi

2021 High quality Aluminum 5005 - ACP 5080 Precision Aluminum Plate Ultra Flatness Surface – Miandi Detail:

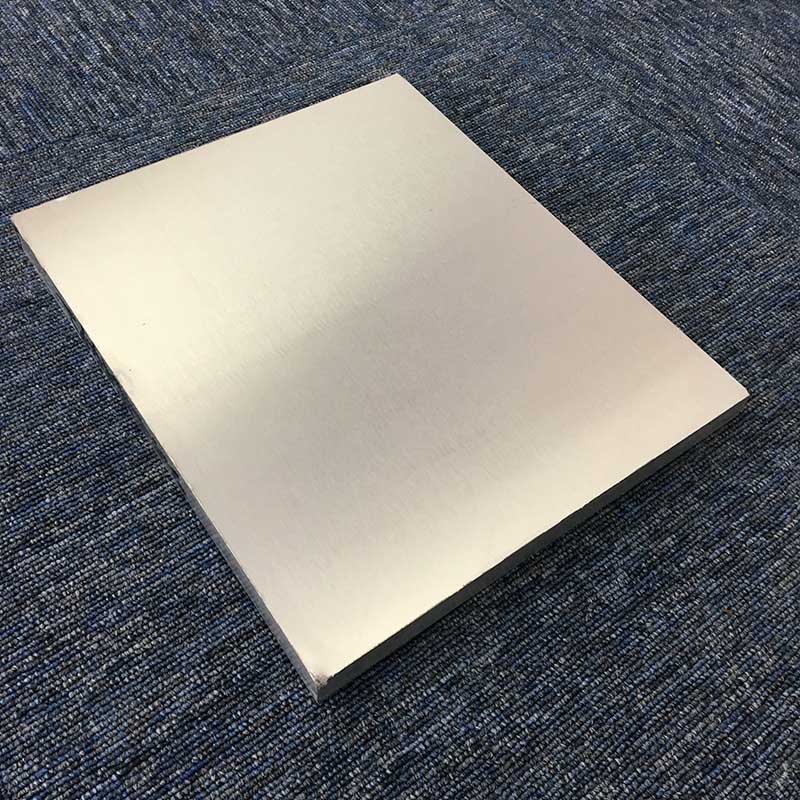

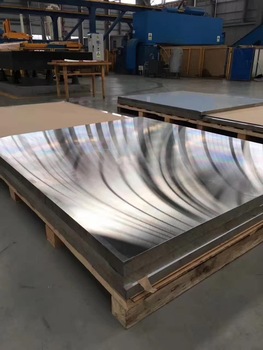

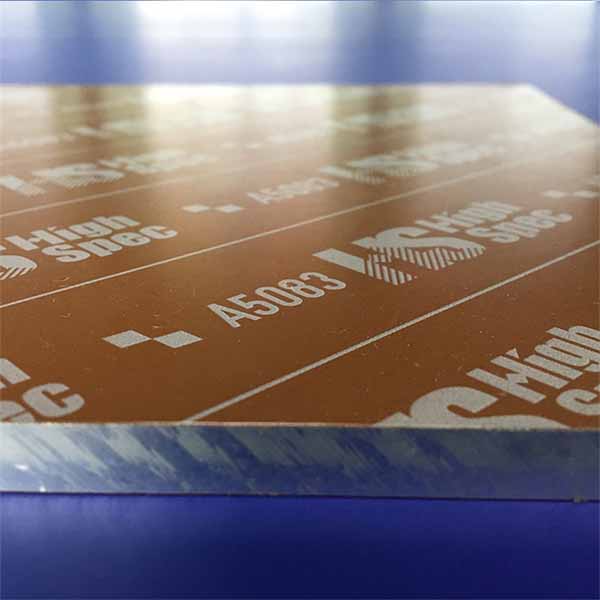

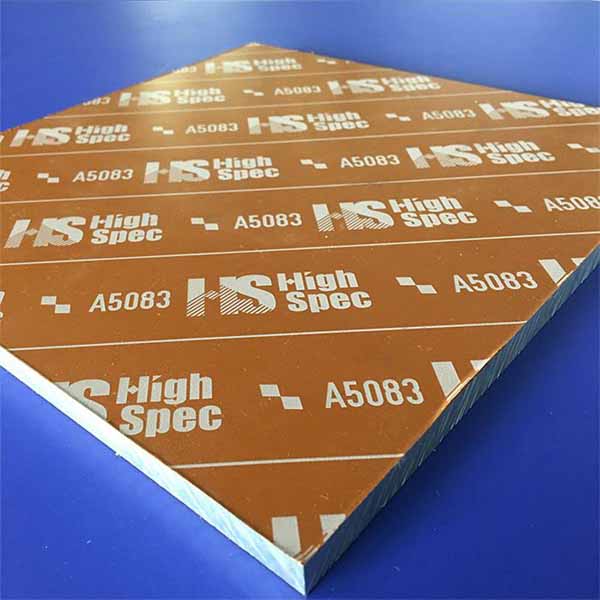

Cutting data display Thickness tolerance AA Grade ±0.05mm, A Grade ±0.1mm. Flatness ≤0.3mm/mete. Equipped with several semi-automatic / automatic precision cutting equipment in the workshop. The cutting plate thickness range is 4mm~100mm, the maximum plate size is 2200*6000mm. Cutting deformation are very small, effectively improve the rate of finished products. The plate size can be customized with customer requirements. Features Surface Luminosity Surface with polish above 400 mesh, customer can directly anodize, no need to milling surface, which can save the processing time. Thickness tolerance Thickness tolerance can touch 0.0mm or +0.05mm, it can completely replace the imported aluminum plate from German and Japan. Precision cutting Better production process, effectively improve the rate of finished products, reduce wasting. Residual elasticity Cutting deformation are very small, better than normal T651 material. Due to better heat treatment and anneal process, the internal elasticity is small.

| Compared with ordinary materials | |||

| Ordinary aluminum plate | Ultra-flat aluminum plate | ||

| Thickness tolerance | For work with strict thickness tolerance, thicker plate are required for complex and time-consuming process before cutting. | Thickness tolerance are very high, no need to cutting separately, and no need to milling the surface, it can drastic reduce the processing cost and time。 | |

| Flat accuracy | The thicker plate with low flat accuracy not only increase cutting cost, but also need processing from thicker plate. | With excellent flatness, maximum with 0.05mm/㎡, it can reduce the cutting cost also the processing time and salary. | |

| Residual elasticity | It was easily deformation during processing due to the big residual elasticity, shall add the process of elastic release annealing. | With low deformation after process, no need release internal elastic, leveling and other treatment. It can reduce the cost and improve efficiency. | |

Applications

ELECTRONIC PRODUCT

It is used in the circuit aluminum substrate panel of electronic products or machinery. The flatness difference of aluminum substrate panel in each step of production process, including raw materials. It is easily to cause inaccurate of stamping dimensions due to the bending of the ordinary aluminum plate during the stamping process, which increases production costs, Ultra-flat plate greatly reduces production costs.

PRECISION INSTRUMENT

Ultra-flatness aluminum plates are widely used in precision instruments, which can be processed into soft pack power battery fixtures, 3C soft pack digital battery fixture forming (assembly) equipment, and related precision battery fixtures, especially in the field of new energy.

MACHINING

The features of the ultra-flatness aluminum plate make more machining companies willing to choose it when processing precision parts, which can well guarantee the size and accuracy of the finished product after processing, and greatly reduce the scrap rate during processing, and improve the qualified rate of finished products.

OTHER APPLICATIONS

Other applications like packaging machinery platform, automated machinery platform, 3D printer, inspection equipment, standard panel, detector, robot arm chassis, etc. Ultra-flat panels can solve the products disqualified problems caused by flatness not touch standard, so they are very popular in the industrial field.

Our Advantage

Inventory and Delivery

We have enough product in stock, we can offer enough material to customers. The lead time can be within 7 days for stock materil.

Quality

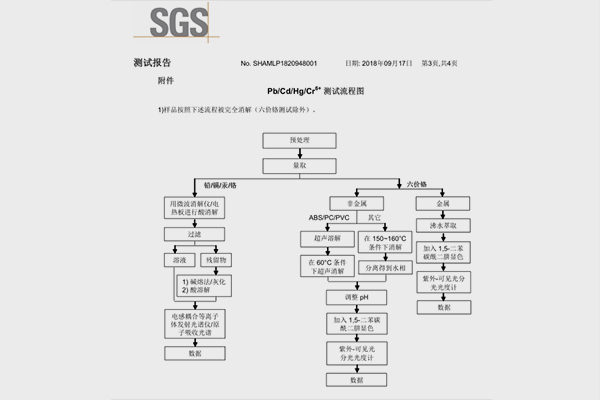

All the product are from the biggest manufacturer, we can offer the MTC to you. And we can also offer Third-Party test report.

Custom

We have cutting machine, custom size are available.

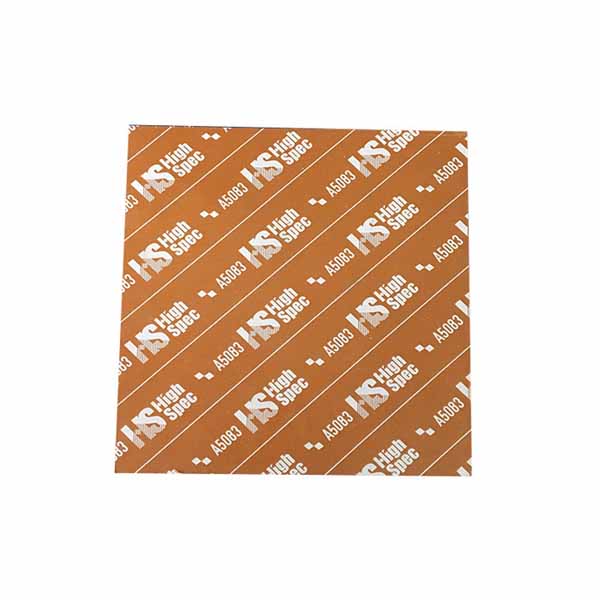

Product detail pictures:

Related Product Guide:

BAE Systems to Modernize Cruiser USS Vicksburg Under $42 Million Navy Contract | 4043 Aluminum Plate

La Marina de Guerra del Perú adjudica un contrato a Aerospace Logistics por dos Lanchas de Interdicción Marítima-noticia defensa.com | Aluminum 5086

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for 2021 High quality Aluminum 5005 - ACP 5080 Precision Aluminum Plate Ultra Flatness Surface – Miandi , The product will supply to all over the world, such as: Sierra Leone, Azerbaijan, Senegal, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.